3 Minutes

Addressing Plastic Pollution and Fossil Fuels in Pharmaceuticals

Global plastic pollution and the heavy reliance on fossil fuels in pharmaceutical manufacturing represent two of the most pressing environmental challenges of our time. In a pioneering effort, researchers at the University of Edinburgh have developed a method that addresses both issues simultaneously by engineering Escherichia coli (E. coli) bacteria to transform waste plastic into the common painkiller acetaminophen (paracetamol).

The Science Behind Biotechnological Conversion

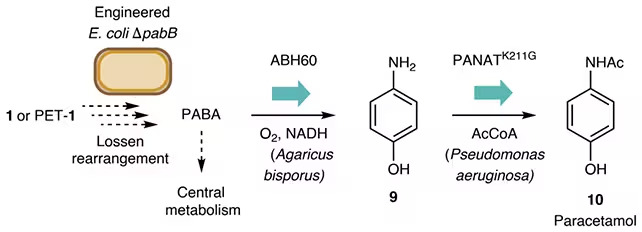

Polyethylene terephthalate (PET), a prevalent plastic used in bottles, food packaging, and textiles, contributes to over 350 million tons of annual waste worldwide. Traditionally, acetaminophen is synthesized from fossil fuel-derived chemicals, which exacerbates environmental concerns. The Edinburgh research team has leveraged synthetic biology advances to create genetically modified E. coli capable of using PET-derived molecules as a substrate for drug synthesis.

The process begins with a chemical breakdown of PET plastic, converting it into smaller molecular building blocks. These intermediates are then metabolized by engineered E. coli, which, thanks to introduced biosynthetic pathways, transform them into nitrogen-containing organic compounds. Using phosphate as a catalyst and a streamlined biochemical workflow, these precursors ultimately yield acetaminophen with remarkable efficiency.

Efficiency and Technological Innovations

One standout feature of this method is its rapid turnaround: the bioconversion completes within 24 hours in a standard laboratory environment and operates at room temperature, eliminating the need for intensive energy inputs typically required for heating or refrigeration. Furthermore, researchers report a conversion yield of 92 percent, underscoring the process's efficiency and potential scalability for industrial application.

Central to the method is the use of the Lossen rearrangement, a classic organic chemistry reaction discovered in the 19th century by German chemist Wilhelm Lossen. In this innovation, the reaction has been adapted for compatibility with living cells, marking a breakthrough in integrating synthetic organic chemistry with biological systems.

Broader Implications for Recycling and Pharmaceutical Manufacturing

The engineered E. coli approach could pave the way for new, environmentally friendly applications beyond PET recycling. Since PET is just one of many plastics choking the environment, adapting the process to other types of plastic and potentially other bacteria could expand the impact on both waste management and green chemistry.

As biotechnologist Dr. Stephen Wallace of the University of Edinburgh explains, "This research shows that PET plastic isn't merely a pollutant or destined for more plastic manufacturing—microorganisms can convert it into valuable new products, some with medical relevance."

Crucially, this technique links natural biochemistry to the innovative capacity of synthetic organic chemistry, illustrating how integrating natural and artificial chemical reactions can lead to sustainable solutions for industrial challenges. With further research and development, such microbial factories could help reshape the future of drug manufacturing, making it cleaner, more sustainable, and less dependent on nonrenewable resources.

Conclusion

This breakthrough demonstrates how advanced biotechnology and green chemistry may work hand-in-hand to address pervasive environmental issues. Engineering E. coli to convert plastic waste into vital medications like acetaminophen not only diverts harmful plastics from landfill and oceans but also reimagines the production of pharmaceuticals without fossil fuel dependence. As researchers expand this approach, the prospect of sustainable recycling methods and environmentally conscious drug synthesis seems more achievable than ever, setting a precedent for innovation at the intersection of environmental science and human health.

Source: doi

Comments