13 Minutes

Overview: Flight 10 and the path to recovery

SpaceX is moving forward with preparations for the 10th full-scale Starship test flight after the Federal Aviation Administration (FAA) closed its inquiry into the vehicle's most recent in-flight failure and cleared the company to resume launches under its current license. The company completed a final propulsion verification — a "spin prime" test — at its Starbase facility in South Texas and returned the vehicle to a hangar for final inspections, heat‑shield touchups and other preflight tasks. SpaceX has set a target date of no earlier than Sunday, August 24 at 6:30 p.m. local time in Texas (23:30 UTC) for the next launch attempt.

The test will again use the full Starship stack: a Super Heavy booster with 33 methane‑fueled Raptor engines and an upper stage called Starship powered by six Raptors. The combined vehicle stands roughly 403 feet (123 meters) tall and represents SpaceX's core architecture for rapid reuse, heavy-lift launches, and future missions to the Moon, Mars and large orbital infrastructure such as Starlink constellations.

This flight will be watched closely by regulators, NASA and the wider spaceflight community because it comes after a period of repeated setbacks for the program. Although Starship achieved a string of high‑profile successes in 2024 — including multiple flights and the first pad catch of a Super Heavy booster — early 2025 has been marked by in‑flight anomalies and a destructive ground test. Flight 10 aims both to close open technical issues and to gather critical reentry and payload deployment data needed for future milestones such as orbital refueling, upper‑stage recovery and human‑rated lunar lander certification.

FAA closure and investigation findings

The FAA announced that it "oversaw and accepted the findings of the SpaceX‑led investigation" into the May in‑flight loss. The agency's final mishap report attributed the probable root cause to "a failure of a fuel component," and the FAA cleared SpaceX to proceed with Flight 10 operations under its current license after reviewing corrective actions.

SpaceX publicly identified a faulty pressurization diffuser on the forward dome of the primary methane tank as the most likely origin of the May failure. Sensors registered a pressure drop in the main methane tank and an anomalous pressure increase in the nose cone above the tank a few minutes after liftoff. The vehicle continued its main engine burn by compensating for the pressure loss, but venting from the nose cone and a worsening fuel leak eventually overwhelmed the vehicle's attitude control system. Autonomous safety software then commanded the upper stage to vent remaining propellant and to "passivate" — actively making the vehicle inert — before an unguided reentry over the Indian Ocean ended the mission prematurely.

Engineers were able to recreate the diffuser failure in ground testing, which led to a redesign intended to better direct pressurant gas into the main fuel tank and to substantially reduce structural stress on the diffuser. The FAA reviewed SpaceX's corrective measures and accepted the results as satisfactory for return to flight.

Ground test explosion and hardware fixes

Before Flight 10 could be scheduled, a separate accident on June 18 destroyed Ship 36 during cryogenic propellant loading for an engine test. The vehicle ruptured on a test stand at the Starbase site, damaging infrastructure and prompting a multi‑point review of pressure vessels and ground operations. SpaceX attributed the June mishap to a failure of a composite overwrapped pressure vessel (COPV) — a high‑pressure nitrogen tank stored inside the payload bay — that ruptured violently.

In response, SpaceX ordered a series of mitigations: reduce COPV operating pressures on upcoming flights, add additional inspections and proof testing, tighten acceptance criteria, and implement a hardware change designed to eliminate the failure mode. The company also retrofitted the remaining active launch pad to accommodate the next ship in line, Ship 37, and conducted a short firing of all six upper‑stage Raptors on August 1 as part of preflight verification.

Technical diagnosis: diffuser, COPV and fuel transfer vulnerabilities

Two distinct technical problems emerged from the recent mishaps: a failed pressurization diffuser associated with the main methane tank and structural vulnerability in a COPV used for tank pressurization. Understanding these subsystems is important because they are central to fuel management and vehicle stability.

- Pressurization diffuser: In liquid‑propellant rockets, tanks must maintain positive pressure so propellants flow predictably to the engines. Pressurization systems use inert gases (often nitrogen) to maintain tank pressure. A diffuser helps spread the pressurant into the tank without creating localized loads. When SpaceX found a diffuser failure on the methane tank forward dome, the resulting pressure imbalance caused unexpected venting and an incremental fuel leak that compromised the vehicle's ability to control its attitude.

- COPV reliability: COPVs store high‑pressure gases in a lightweight composite overwrapped design. They are widely used in aerospace, but they require strict manufacturing and acceptance testing because material flaws or damage can cause catastrophic rupture. SpaceX's investigations concluded the COPV in Ship 36 likely sustained damage that led to its failure during propellant loading. Lowering operating pressures and stricter testing aim to remove this risk from the near‑term flight program.

The combination of these issues — pressurization failures and pressure‑vessel integrity — highlights how gas management and internal plumbing are as mission‑critical as engines or heat shields. Fixes in both domains are central to returning to reliable, repeatable test flights.

Mission objectives for Flight 10

SpaceX has stated Flight 10 will continue to expand the operating envelope of the Super Heavy booster and will include multiple planned landing‑burn tests. Primary objectives include:

- Heat‑shield and reentry experiments: The flight will collect data on several different heat‑shield tile materials, both ceramic and metallic, installed on Starship's stainless‑steel skin. Heat‑shield performance is essential to make the upper stage reusable; returning from orbital speeds presents higher thermal loads than the booster reentry. Engineers want to know which tile materials and attachment methods survive reentry and which produce unacceptable hot spots.

- Payload deployment rehearsal: The mission is expected to attempt deployment of spacecraft simulators sized to mimic next‑generation Starlink satellites. Previous flights have included similar payloads in the flight plan, but earlier failures prevented deployment tests.

- Booster descent experiments: Rather than attempting a pad catch at Starbase, the Super Heavy booster will aim for a controlled splashdown in the Gulf of Mexico. This will allow SpaceX to experiment with different engine mixes and throttle strategies during final descent, including contingency scenarios to mitigate problems with one of the primary landing engines.

- Expanding the flight envelope: Engineers will push alternating flight conditions for the booster — but within revised safety margins — to learn structural limits and fluid dynamics in descent. SpaceX previously flew steeper angles of attack that stressed internal plumbing and may have contributed to structural failures; those operating parameters have been adjusted.

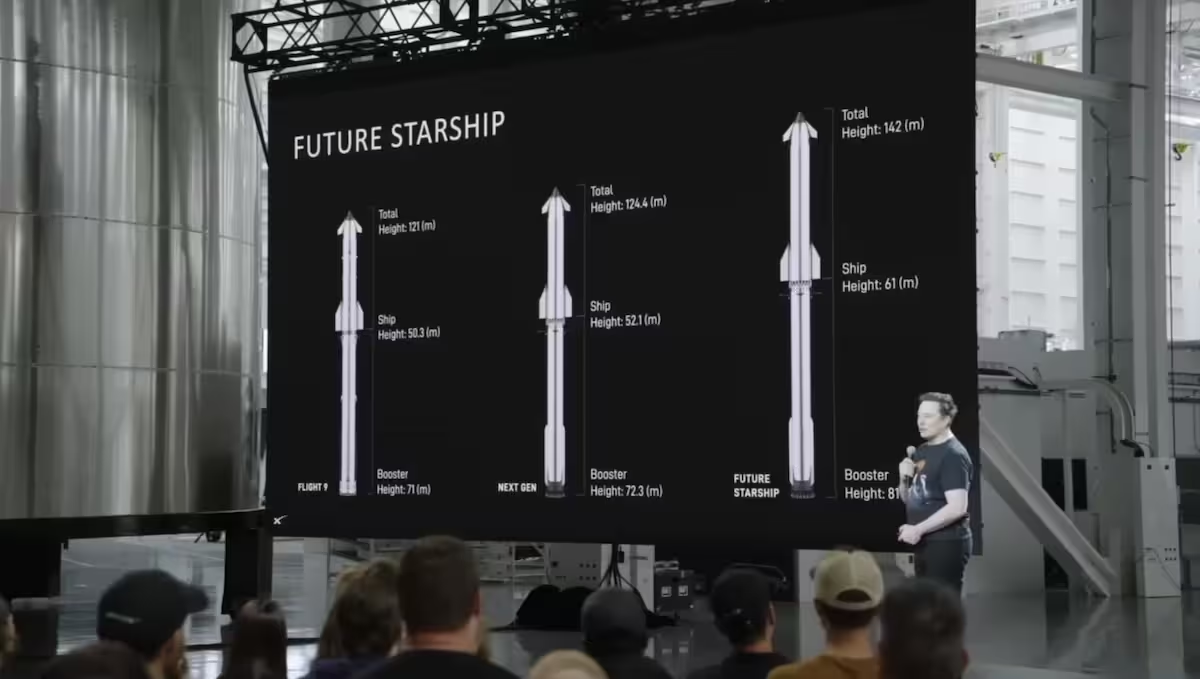

Collecting this data will inform the design of Starship's next configuration, commonly referred to as Version 3 (Block 3), which will be taller and include incremental improvements to Raptor engines and subsystems.

Heat shield, reusability and the path to orbital operations

One of the program's most critical engineering challenges is developing a heat shield capable of surviving atmospheric reentry from orbital velocity. Returning the upper stage intact, then performing a propulsive or pad catch recovery, requires tile materials and attachment methods that can tolerate the extreme heating and mechanical loads of a hypersonic descent.

In 2024, Starship achieved multiple controlled splashdowns and even success in recovering a Super Heavy booster at the pad — milestones that illustrated the potential of rapid reuse. However, in 2025 several test flights ended before the upper stage completed reentry, leaving gaps in knowledge about heat‑shield durability. Sensors on past flights detected hot spots where tiles were missing or had been damaged, and those observations are now central to Flight 10's experimental payload.

A reusable upper stage would be transformational: it would lower marginal launch costs and enable ambitious mission architectures such as in‑orbit refueling — a prerequisite for large interplanetary missions and for Starship's role in NASA's Artemis lunar lander plan. Until the upper stage routinely survives reentry and is recovered, these capabilities remain demonstrable objectives rather than operational realities.

Program context: Starlink, Artemis and the Mars vision

SpaceX's Starship program is strategic for multiple missions. NASA selected Starship as Human Landing System (HLS) for the Artemis program to return astronauts to the lunar surface. A human‑rated Starship will need to meet stringent reliability and safety standards; successful test flights and validated corrective actions are essential to that certification process.

Separately, Starship will be integral to scaling SpaceX's Starlink broadband constellation. Starship's large payload capacity could rapidly deploy thousands of satellites, reducing the time and cost to build orbital infrastructure. Beyond Earth orbit, founder Elon Musk has repeatedly linked Starship to the long‑term vision of building a settlement on Mars, a plan that depends on proven reusability, in‑orbit refueling, and mass production.

Delays in reaching upper‑stage reuse and orbital refueling have pushed those ambitions outward in time. SpaceX had hoped to execute those demonstrations in 2025; after recent setbacks, they are now unlikely to occur before the following year. Each incremental test — and the lessons learned from failure — feed directly into the roadmap for Block 3 and beyond.

What success on Flight 10 would mean

A broadly successful Flight 10 would not necessarily mean immediate operational capability, but it would represent meaningful progress toward resolving three categories of risk: pressurization and plumbing reliability, COPV integrity and ground‑test safety, and heat‑shield survivability. Achieving the planned payload deployment and gathering robust reentry telemetry would give engineers concrete data to validate materials and attachment strategies. Demonstrating controlled booster descent modes under revised constraints would expand the booster recovery toolbox.

Regulatory clearance from the FAA and transparent reporting about failure analyses also matter for public trust and program pacing. NASA and other customers must see demonstrable corrective actions and repeatable test results before assigning critical missions to a vehicle slated to carry crew or high‑value payloads.

Near‑term hardware and configuration roadmap

SpaceX is working with two remaining Version 2 (Block 2) vehicles in its inventory before transitioning to Version 3, which will include structural and engine upgrades — notably improved Raptor engines. Company statements emphasize an iterative development model: every flight and ground test contributes lessons that are rapidly folded into subsequent builds. SpaceX has said two more flights remain with the current generation, each designed to expand the envelope of vehicle capabilities on the route to fully reusable rockets.

Operational improvements in the near term are focused on stricter COPV acceptance testing, lowered operating pressures, redesigned pressurization diffusers, and refined descent profiles for the Super Heavy booster. Taken together, these changes are meant to reduce single‑point failures and create greater margin for unanticipated loads during flight and descent.

Risks and public safety considerations

Large prototype rockets inherently carry risk. Flight trajectories for Starship tests cross populated downrange areas and international airspace, as demonstrated when debris landed near the Bahamas and Turks and Caicos during earlier flights. FAA oversight is designed to ensure public safety through licensing, environmental review and mishap investigations. The agency's acceptance of SpaceX's investigation and corrective actions is a key procedural step toward risk‑informed flight resumption, but ongoing transparency and successful follow‑on flights will be essential to maintain regulatory and public confidence.

Conclusion

SpaceX is preparing Flight 10 to address a string of recent engineering setbacks by implementing hardware redesigns and operational changes. The FAA has closed its inquiry into the May in‑flight failure and approved SpaceX to proceed under its current license after the company identified a faulty pressurization diffuser and proposed corrective actions. Additional mitigations followed the June ground‑test COPV rupture that destroyed Ship 36.

Flight 10 will seek to gather definitive data on heat‑shield materials, attempt payload deployment simulations, and test new descent control modes for the Super Heavy booster. These experiments are essential stepping stones toward upper‑stage reusability, orbital refueling demonstrations and human‑rated lunar missions under Artemis. While there is no single test that will validate the full Starship vision, a successful Flight 10 would mark a decisive step forward — not just for SpaceX, but for the long‑term goals of large, reusable launch systems and future deep‑space exploration.

Keywords: Starship, Super Heavy, Raptor engines, FAA investigation, COPV, heat shield, reusability, Starbase, Starlink, Artemis, orbital refueling, pressurization diffuser, cryogenic propellant, flight test,

Source: arstechnica

Leave a Comment