5 Minutes

Breakthrough: Electric Motors without Metal Conductors

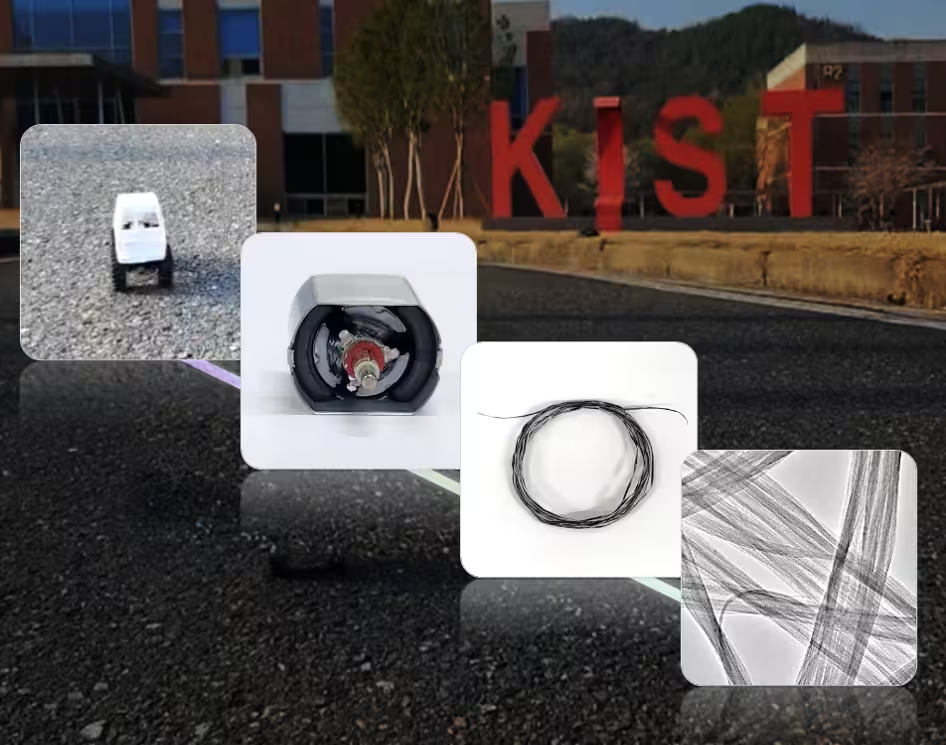

A research team led by Dr. Dae-Yoon Kim at the Korea Institute of Science and Technology (KIST) has demonstrated an electric motor whose coil is made entirely from carbon nanotubes (CNTs) — with no metal conductors. The prototype showed reliable RPM control in response to input voltage changes, proving the concept that electrical energy can be converted into rotational motion using a metal-free conductor. This development promises to reshape thinking about lightweight electric motors used in electric vehicles (EVs), drones, spacecraft, and robotics.

What makes CNT coils special?

Carbon nanotubes are one-dimensional, cylindrical nanomaterials made of carbon atoms arranged in a hexagonal lattice. CNTs are far lighter than copper and many traditional metals, while offering high electrical conductivity, strong tensile strength, and good thermal conductivity. Those attributes make CNT coils a compelling option for engineers pursuing lightweight electric motor designs and battery range improvements.

Key product features of the CNT coil motor

- Metal-free conductor: The coil is entirely composed of purified CNTs, removing dependence on copper or aluminum wires.

- Lightweight construction: Lower coil mass contributes to overall motor and system weight reduction.

- Stable RPM control: Prototype motors demonstrated predictable RPM response across varied input voltages.

- Improved conductivity after purification: A new processing method significantly reduces metallic impurities from CNT surfaces.

Innovative purification: liquid crystal alignment

A major barrier to using CNTs in real-world electrical components has been residual catalyst metals left from manufacturing. These metallic nanoparticles adhere to CNT surfaces and disrupt electrical pathways. The KIST group developed a novel purification approach leveraging the alignment behavior of liquid crystals — the intermediate state of matter between liquids and solids. As CNTs align within the liquid-crystal medium, agglomerates break apart and metallic residues are selectively removed without damaging the nanotube architecture. The result is high-quality CNT material with conductivity sufficient for motor coils.

Comparisons and trade-offs with copper coils

Compared with conventional copper windings, CNT coils offer major potential benefits: reduced mass, lower reliance on copper supply chains, and immunity to copper price volatility. However, important technical comparisons remain: copper still leads on mature manufacturing scale, proven thermal management, and cost per conductor in many applications. The KIST team notes the need for thorough benchmarking of power density, energy efficiency, heat dissipation, and lifecycle cost against copper-based motors under real-world operating conditions.

Advantages

- Weight savings that can boost vehicle range and flight time for drones and reduce launch mass for spacecraft.

- Supply-chain resilience by reducing copper demand and exposure to commodity price swings.

- Potential cross-industry applications in batteries, semiconductor pellicles, and robotic cabling thanks to the CNT purification technology.

Limitations and future work

Scaling the process, ensuring consistent thermal performance, integrating CNT coils into mass-produced motors, and validating long-term reliability are essential next steps. Extensive testing on power density and efficiency will determine whether CNT coils can match or exceed copper in commercial EV traction motors and high-power industrial applications.

Use cases and market relevance

Short-term use cases include lightweight motors for drones, robotics, and specialty aerospace systems where every gram matters. In the medium to long term, if the technology scales economically, CNT-based coils could appear in electric vehicle motors, industrial drives, and high-performance consumer electronics — offering manufacturers a copper alternative that aides sustainability and cost predictability.

“By developing a new concept of CNT high-quality technology that has never existed before, we were able to maximize the electrical performance of CNT coils to drive electric motors without metal,” said Dr. Dae-Yoon Kim of KIST. The team plans to advance CNT material localization for conductive battery components, semiconductor pellicles, and robotic cabling as part of broader commercialization efforts.

For technology leaders and product developers, this research highlights an emerging materials pathway: metal-free conductors that could unlock lighter, more efficient, and more sustainable electric systems — provided the challenges of scale, thermal management, and cost-efficiency are successfully addressed.

Source: kist.re

Leave a Comment