3 Minutes

AI maps battery aging to extend lifespan and improve safety

Electric vehicle (EV) batteries often become the first major component to degrade, increasing replacement costs and slowing the shift to electrified transport. Researchers at Uppsala University, in collaboration with Aalborg University, have developed a novel AI-driven model that gives a far more accurate picture of battery aging and internal chemical processes. Published in Energy & Environmental Science, the model promises up to a 70% increase in the robustness of battery health predictions compared with current methods.

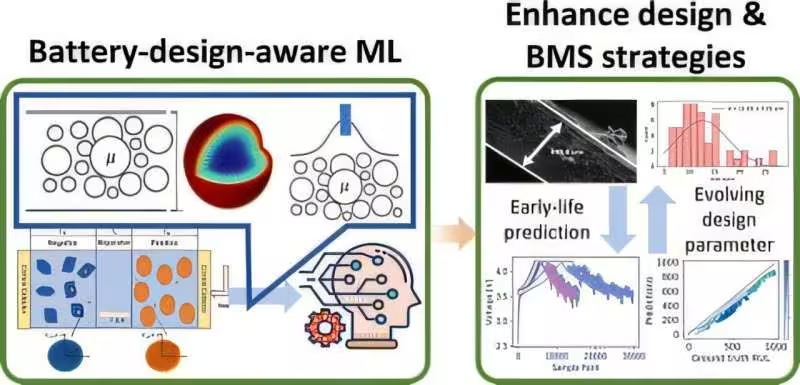

How the hybrid AI model works

The team combined thousands of short charging-segment measurements with a detailed, physics-informed representation of the cell’s internal chemistry. Instead of treating batteries as black boxes, this hybrid approach fuses machine learning with electrochemical modeling to trace the specific reactions that produce power and drive degradation. According to the study lead, Professor Daniel Brandell, this visibility enables smarter control strategies that keep cells healthier for longer.

Key technology features

- Physics-informed machine learning: blends empirical data with chemical-process models for accurate state-of-health (SoH) inference.

- Short-segment charging analytics: uses short charging and discharging snippets, which reduce data sensitivity and simplify field deployment.

- High prediction robustness: researchers report up to 70% better robustness in battery health predictions.

- Compatibility with battery management systems (BMS): designed to augment existing BMS and predictive maintenance tools.

Advantages over conventional approaches

Traditional black-box AI models often require large, continuous datasets and can miss the chemical root causes of aging. By contrast, this hybrid model delivers:

- Improved SoH estimation and lifetime forecasting, reducing premature replacements.

- Better safety prediction by detecting design flaws and harmful side reactions from charge/discharge patterns.

- Lower data-privacy risk — useful analytics derived from short, anonymizable segments rather than full-drive logs.

Comparisons and market relevance

Compared with pure machine learning and purely analytical electrochemical models, the hybrid method trades off extreme data hunger and opaque decision-making for explainability and efficiency. For automakers and battery manufacturers, this approach can reduce warranty costs, extend usable battery life, and accelerate EV adoption by lowering total cost of ownership (TCO). For regulators and safety engineers, the model offers a route to proactive risk identification and mitigation.

Use cases and real-world impact

Potential applications include:

- OEM integration into next-gen battery management systems to enable adaptive charging strategies.

- Fleet operators and ride-hailing services using predictive maintenance to lengthen pack lifetimes and minimize downtime.

- Charge-station networks optimizing fast-charging profiles to reduce degradation.

- Second-life battery marketplaces and recycling centers assessing residual capacity and safety more reliably.

Outlook: accelerating electrification with safer batteries

By revealing what happens inside cells and producing robust battery health predictions from limited, privacy-friendly datasets, this AI model offers a pragmatic path to safer, longer-lasting EV batteries. As vehicle electrification scales, tools that combine machine learning with electrochemical insight will be critical for optimizing battery life cycles, lowering costs, and meeting safety standards across global markets.

Source: techxplore

Leave a Comment