5 Minutes

Ultra-thin design meets thermal innovation

Apple’s upcoming iPhone 17 Air promises to be the company’s slimmest smartphone yet at just 5.5mm thick. While a thinner profile appeals to design-minded buyers, it creates engineering challenges: smaller battery capacity and reduced internal space can increase the risk of thermal throttling, especially when packing a high-performance chip like the rumored A19 Pro. New reporting indicates Apple is addressing these thermal limits with a substrate miniaturization technology called "Copper Post," developed by LG Innotek. The goal: keep the SoC running at higher sustained speeds without sacrificing the phone’s slim dimensions.

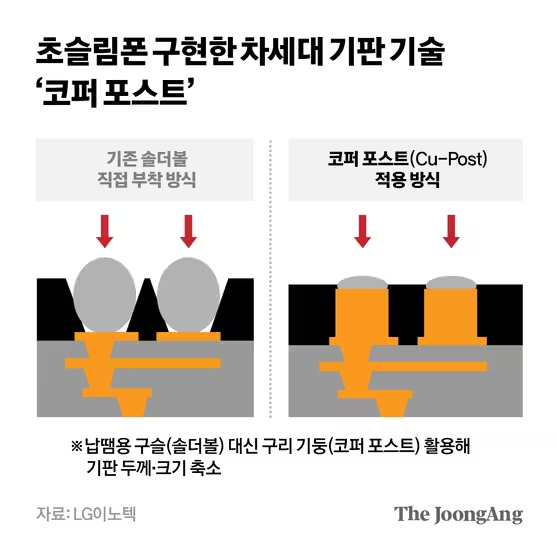

What is Copper Post?

Copper Post is a semiconductor substrate miniaturization technique that replaces or augments traditional solder-ball connections between the logic board and the SoC substrate. Instead of relying only on conventional solder balls, LG Innotek’s approach erects small copper posts and places semicircular solder balls on top. This structural change reduces the overall footprint of the substrate and lets manufacturers produce components up to 20% smaller, enabling tighter packaging and slimmer chassis while preserving electrical and thermal performance.

How Copper Post helps A19 Pro thermals and performance

By shrinking the semiconductor substrate and improving the interconnect layout, Copper Post gives Apple more flexibility in internal thermal design. A smaller package area means Apple can optimize material placement, heat paths, and proximity of the SoC to internal cooling solutions. In practice, that can translate to fewer instances of thermal throttling during sustained tasks — gaming, 4K video editing, or heavy AI workloads — even inside a 5.5mm body.

Here is how Copper Post will look and function when in a smartphone

Features and technical advantages

- Substrate miniaturization: enables up to ~20% smaller semiconductor modules.

- Improved interconnect density: copper posts allow tighter packing of solder balls and traces.

- Thermal path optimization: reduced substrate area gives engineers more options to route heat away from the SoC.

- Mass-production readiness: LG Innotek designed Copper Post for scalable manufacturing, which is critical for high-volume iPhone models.

Comparison: Copper Post vs. vapor chamber

Apple’s Pro-tier iPhones have traditionally relied on vapor chambers to spread and dissipate heat across a larger internal area. Vapor chambers are very effective for thicker devices with sufficient internal volume. Copper Post, by contrast, is a substrate-level innovation that enables smaller packaging and better thermal performance in constrained spaces. For the iPhone 17 Air’s ultra-slim profile, Copper Post could be a better fit because it reduces the need for bulky heat spreaders; however, whether it matches a vapor chamber’s raw cooling capacity in prolonged peak loads remains to be seen.

Use cases: who benefits most?

Users who demand both a slim handset and high sustained performance will see the most benefit. Mobile gamers, content creators doing on-device video editing, and professionals using AI-driven apps should experience fewer slowdowns. The miniaturization also helps foldable designs where two halves must accommodate electronics without extra thickness — a key reason Copper Post is already being discussed for future foldable iPhone concepts.

Market relevance and roadmap

LG Innotek’s Copper Post first appeared commercially on the communication module of the iPhone 16e earlier this year and now looks set for broader use in the iPhone 17 Air. If the rollout succeeds, it could influence other OEMs to adopt substrate miniaturization to balance slim industrial design with high-performance silicon. For Apple, Copper Post helps preserve product differentiation — designing thinner devices without giving up the speed advantage of the A19 Pro.

Final thoughts

Copper Post is not a one-to-one replacement for the vapor chamber used in the iPhone 17 Pro and Pro Max, but it represents a smart, targeted approach to thermal engineering for ultra-thin devices. By combining semiconductor substrate miniaturization with careful internal thermal architecture, Apple may deliver an iPhone 17 Air that feels both elegant and powerful — keeping the A19 Pro closer to its performance ceiling even inside a 5.5mm frame.

Source: wccftech

Leave a Comment