4 Minutes

BMW's newest factory goes live in Hungary

BMW Group's fresh production hub in Debrecen, Hungary, will be the assembly home for the second-generation BMW iX3. The plant opens production late October 2025 and is positioned as a flagship of BMW's iFactory strategy, prioritizing efficiency, sustainability and digitalization from the ground up.

Built virtually, optimized in reality

Debrecen was designed as a digital-first facility: engineers tested production flows and validated processes in the BMW Group Virtual Factory, where the site recorded a 'virtual start of production' back in March 2023. That two-plus year head start allowed BMW to refine workflows using digital twins before real-world lines and equipment were installed, reducing commissioning time and early production risk.

Renewable energy at the center

Uniquely, Plant Debrecen will draw electricity exclusively from renewable sources during normal operation, making it BMW Group's first production site run on 100% green power in routine conditions. The company estimates that producing one iX3, including its battery pack, reduces CO2e by roughly 90% compared with conventional benchmarks — to about 34 kg per vehicle.

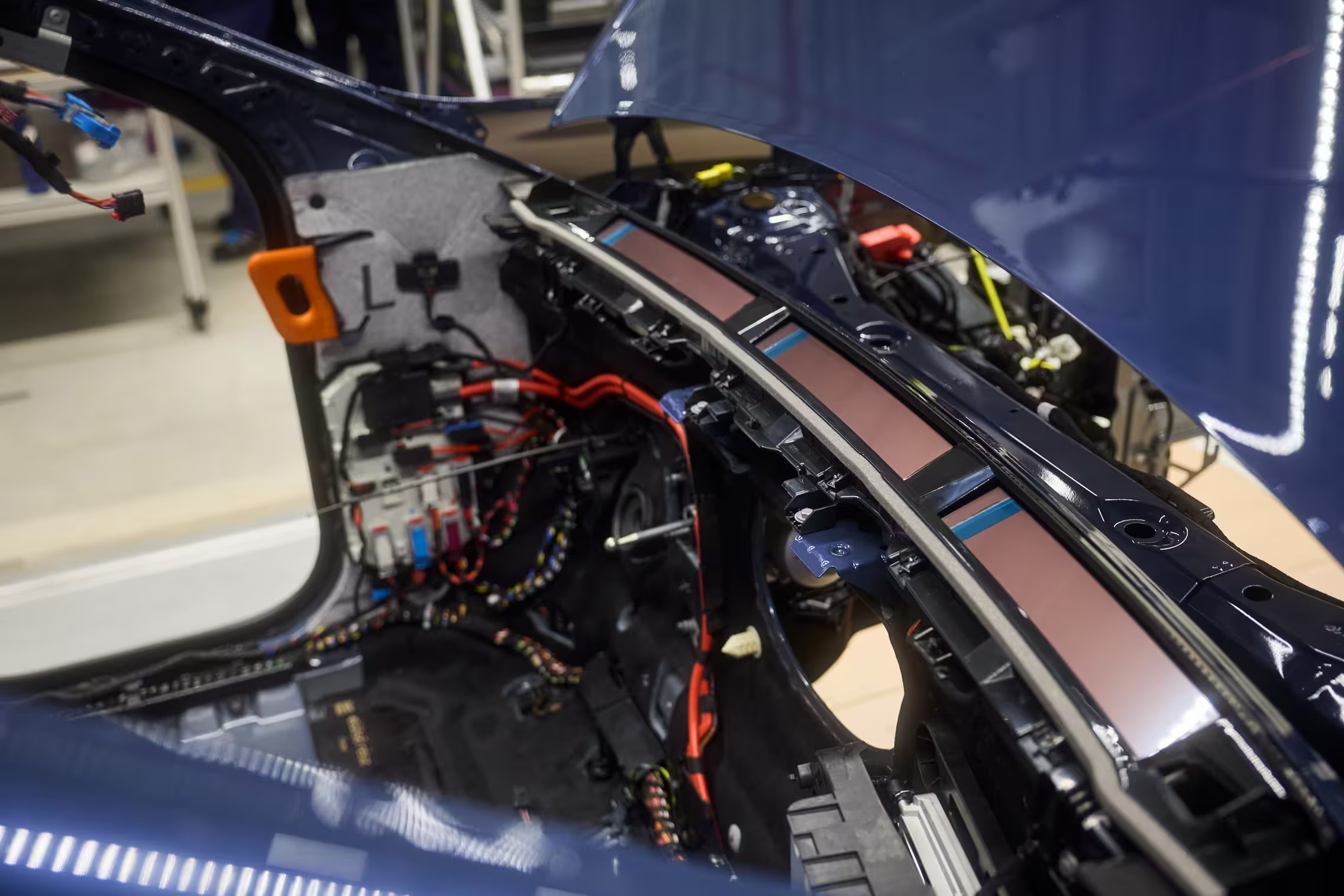

Where AI and automation meet quality

Artificial intelligence is embedded across the assembly process. BMW's in-house AIQX (Artificial Intelligence Quality Next) platform supports tasks such as automated quality assurance, anomaly detection and process optimization. AI complements other iFactory elements like virtual planning, data-driven process control and flexible automation to increase throughput while keeping defect rates low.

- Digital twin validation and virtual testing

- AI-driven quality checks via AIQX

- On-site high-voltage battery assembly

- Renewable electricity powering operations

What the new iX3 brings

The Neue Klasse-based iX3 represents a significant technical step for BMWs compact luxury crossover segment. The iX3 50 xDrive pairs the sixth-generation BMW eDrive with a new high-voltage battery that uses cylindrical cells and 800-volt technology. Power figures for the 50 xDrive version are around 463 hp and 476 lb-ft of torque, with advanced drivetrain management branded as BMW Dynamic Performance Control and a new 'Heart of Joy' control concept.

Inside, BMW launches its Panoramic iDrive built on BMW Operating System X, integrating infotainment, vehicle functions and driver assistance into a more intuitive digital architecture. BMW also highlights the car's new design language as 'timeless, modern and reduced', aligning aesthetics with the underlying software-defined architecture.

Competitive context

The iX3 will enter a busy market. Rivals such as the Audi Q6 e-tron, Cadillac Optiq and Mercedes models fitted with EQ Technology are already contesting the premium electric crossover space, particularly in the US. BMW's strategy with the iX3 and the Debrecen plant is to combine manufacturing sustainability and cutting-edge software to sharpen competitive advantage.

At full capacity the Debrecen factory will employ more than 2,000 people and will assemble high-voltage battery packs on-site, keeping a large portion of value creation within the plant. For buyers and industry watchers, Debrecen is an example of how automakers are merging green energy, digital engineering and AI to lower environmental footprint while scaling EV production.

Highlights:

- Series production starts: late October 2025

- Platform: Neue Klasse

- Key technologies: 6th-gen eDrive, 800V battery with cylindrical cells, BMW Panoramic iDrive (OS X), AIQX

- Sustainability target: ~34 kg CO2e per vehicle (including battery)

For car enthusiasts and fleet managers alike, BMW Group Plant Debrecen will be a useful case study in how electric vehicle manufacturing evolves toward carbon reduction, digital validation and AI-assisted quality control.

Source: autoevolution

Leave a Comment