4 Minutes

Ferrari flips the script with an inverted hydrogen internal-combustion engine

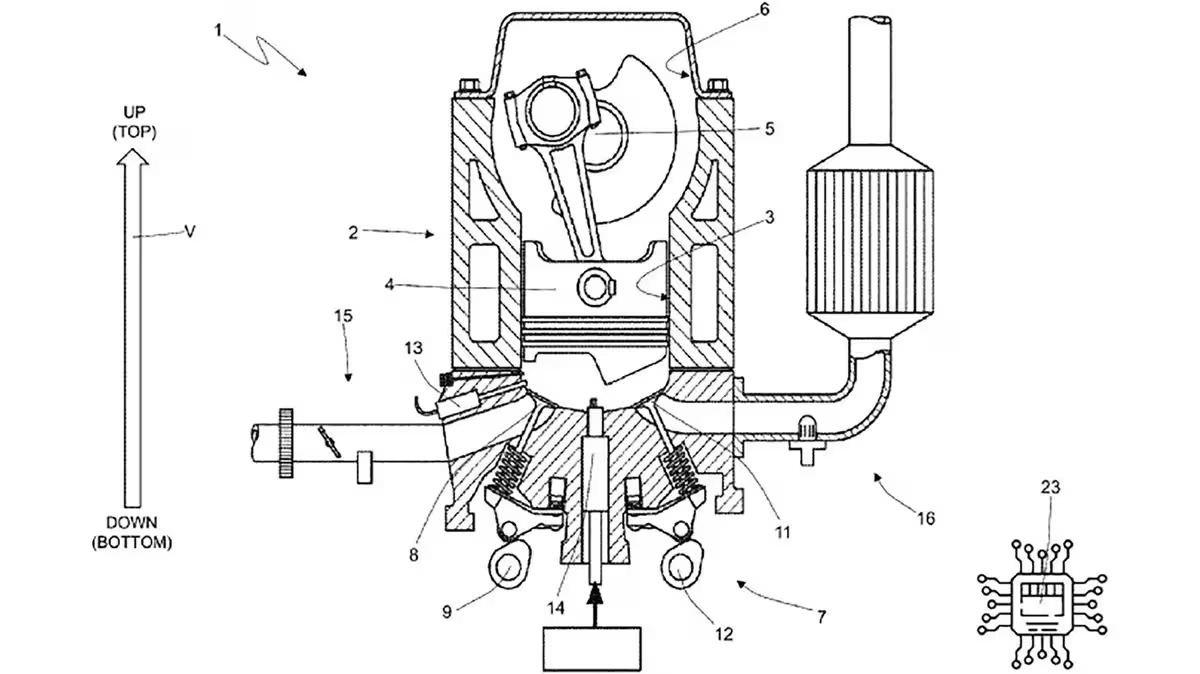

Ferrari has always been willing to push the boundaries of engine design, from racing prototypes to roadgoing V12s. Their latest experiment may be the boldest yet: an inverted hydrogen internal combustion engine that rethinks the traditional layout to make room for large hydrogen tanks. While the packaging benefits are clear, the engineering challenge is obvious too — how do you keep vital moving parts lubricated when gravity works against you?

What 'inverted' means for engine architecture

Conventional internal-combustion engines place the crankshaft down low and the combustion chambers above, with oil stored in a sump beneath the crank. Gravity helps oil return to the pan after being pumped upward, creating a reliable film on bearings, pistons and other components.

Ferrari's inverted design flips that arrangement: the crankshaft sits higher in the block and the oil reservoir is relocated under the hood. That frees space low in the chassis to better package bulky hydrogen tanks — a major priority if hydrogen ICEs are to be practical in performance cars. But it also creates a new risk: oil naturally drains downward, potentially flooding cylinder bores, fouling spark plugs, causing smoky combustion or even seizing the engine.

Ferrari's solution: a controlled dry-sump system with ECU-managed pumps

Instead of a conventional wet-sump, Ferrari proposes a dry-sump lubrication system that stores oil in a separate tank. Key elements include:

- Electric oil pumps controlled precisely by the engine ECU.

- Jet nozzles under the crank to supply oil to bearings and moving parts during operation.

- A timed cutoff: the ECU shuts the oil feed shortly before engine shutdown — typically around one second, adjustable from 0.5 to 2.5 seconds.

- Centrifugal return: when pumps stop, remaining oil is flung away from the crank by rotation and returns to the remote reservoir.

This rapid, controlled sequence maintains a protective lubrication film while the engine runs, yet prevents oil pooling in the cylinders once it stops. It's a neat marriage of mechanical design and electronic control that addresses the inverted layout's core weakness.

Why this matters for hydrogen ICEs and performance cars

Ferrari's approach highlights a broader trade-off in alternative-fuel performance engineering: packaging versus legacy architecture. By reimagining the engine layout, Ferrari gains space for hydrogen tanks without compromising center of gravity or aerodynamics — but only if oiling, sealing and combustion safety are solved.

The marque's long-standing technical collaborations, including with lubricant specialists like Shell, suggest these trials are more than conceptual exercises. Refinement of bespoke lubricants and pump strategies will be critical if an inverted hydrogen engine moves from prototype to production.

- Key benefits: better hydrogen tank integration, potential weight and balance gains, continuation of combustion-driven performance heritage.

- Key risks: system complexity, calibration needs, and unknowns around real-world durability and emissions control.

Outlook

Whether Ferrari will bring the inverted hydrogen ICE to customers remains uncertain. For now, the project is a clear signal: Ferrari is willing to question century-old engine norms to explore hydrogen as a performance fuel. Even if it never reaches showroom cars, the engineering lessons could influence future hybrid and hydrogen powertrains across the industry.

'It’s an elegant, high-risk idea,' one industry engineer might say. 'The devil is in the control software and lubrication strategy.' That sums up the project well — innovation grounded in precise engineering rather than novelty for its own sake.

Leave a Comment