5 Minutes

Researchers led by Peking University have reported a stretchable, rubber-like thermoelectric material that converts the temperature difference between human skin and ambient air into electrical power. Published in Nature, the work demonstrates an n-type thermoelectric elastomer that combines high elasticity with improved electrical performance, opening pathways to self-powered wearable sensors, health-monitoring patches and potentially implantable devices that harvest body heat.

How the material generates electricity

The device operates on the principle of thermoelectricity: a temperature gradient produces a flow of charge carriers, which generates an electric current. In practical terms, the human body at roughly 37°C presents a warm surface relative to surrounding air (often 20–30°C). When the elastomer is placed against skin, the persistent skin-to-air temperature difference drives continuous electrical generation without moving parts.

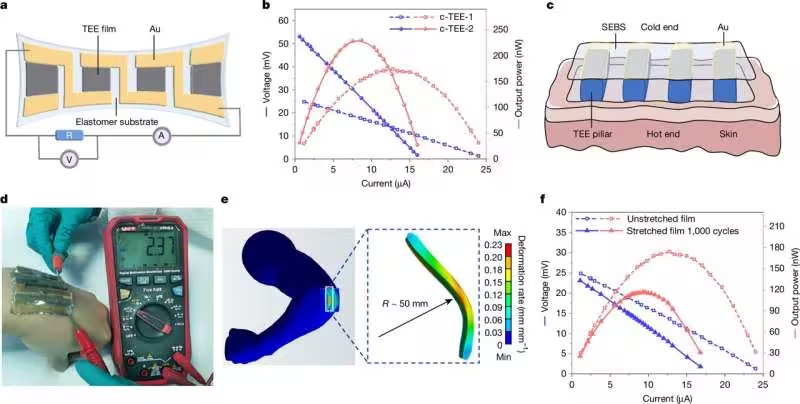

Thermoelectric conversion depends on three material properties: the Seebeck coefficient (voltage per unit temperature difference), electrical conductivity, and thermal conductivity. The Peking University team engineered an elastic polymer composite that preserves favorable electronic transport while maintaining low thermal conductivity and excellent mechanical compliance — a rare combination that yields useful power from small temperature differences typical of the human body.

Materials engineering and key innovations

A central advance in the reported work is the development of an n-type thermoelectric elastomer that remains conductive under mechanical deformation. Historically, making materials both highly stretchable and electrically conductive has been a major challenge: conductive fillers or rigid phases often compromise elastic recovery, while soft polymers typically lack electronic performance.

The research team addressed this with a polymer composite architecture and targeted molecular doping. They added a dopant, N-DMBI (N,N'-dimethylbenzimidazoline), in trace amounts to enhance carrier density and electrical conductivity without embrittling the matrix. The doped elastomer shows substantial improvements in power-generating performance compared with undoped counterparts while preserving rubber-like behavior.

Mechanical performance

Mechanically, the composite recovers its original shape after being elongated to approximately 150% of its resting length and can tolerate extreme strains reported above 850% in laboratory testing. Such resilience means devices made from the material can conform tightly to curved or moving body surfaces — wrists, chests or clothing — maintaining thermal contact and reliable energy harvesting while the wearer moves.

Potential applications and implications

By enabling continuous energy harvesting from the skin, these thermoelectric elastomers could reduce or eliminate the need for bulky batteries in many small, low-power devices. Immediate applications include wearable health monitors, fitness trackers, and environmental sensors that operate as patches or garment-integrated modules. For medical uses, self-powered cardiac or metabolic monitoring patches would be able to run for extended periods without recharging.

Longer-term prospects extend to implantable electronics that harvest metabolic heat to sustain low-power devices, and to distributed Internet of Things (IoT) sensors that operate maintenance-free in garments or on skin. However, translation to products will require further work on stability, biocompatibility, sustained power output under real-world conditions, and scalable manufacturing.

Experiment details and performance metrics

The Nature article describes fabrication steps, electrical and mechanical characterization, and prototype demonstrations. Key performance metrics reported include the material’s Seebeck response, electrical conductivity after N-DMBI doping, and power output under representative skin-to-air temperature gradients. The study also documents repeated stretching and recovery cycles to assess durability under conditions relevant to wearables.

Expert Insight

Dr. Maya Singh, a materials engineer who researches flexible energy systems, commented: "This study addresses a persistent trade-off in soft electronics: combining high electrical performance with extreme elasticity. The targeted use of molecular dopants like N-DMBI, together with a compliant polymer network, is a pragmatic path toward real-world wearable thermoelectrics. The next milestones will be long-term stability, encapsulation for sweat and motion, and integration with low-power sensors and power-management circuits."

Related technologies and future prospects

Thermoelectric elastomers complement other energy-harvesting approaches for wearables, such as piezoelectric generators (harvesting motion), photovoltaic fabrics (harvesting light) and biochemical fuel cells (harvesting sweat metabolites). Hybrid systems that combine multiple harvesters can increase overall reliability and power budgets. For commercial adoption, engineers must also optimize device form factors, matching impedance and energy-storage strategies (small capacitors or thin-film batteries) to smooth variable power output.

Conclusion

The Peking University-led study represents an important materials advance toward self-powered wearable electronics. By demonstrating an n-type thermoelectric elastomer that retains conductivity under large strains and benefits from molecular doping, the work shows how body heat can be harvested continuously in a flexible, skin-conforming form factor. Continued progress on stability, integration and manufacturing will determine how quickly this technology moves from laboratory prototypes to everyday health monitors, garments and implantable systems that no longer rely on frequent recharging.

Source: techxplore

Leave a Comment