5 Minutes

Breakthrough: Microbial production of a PET alternative

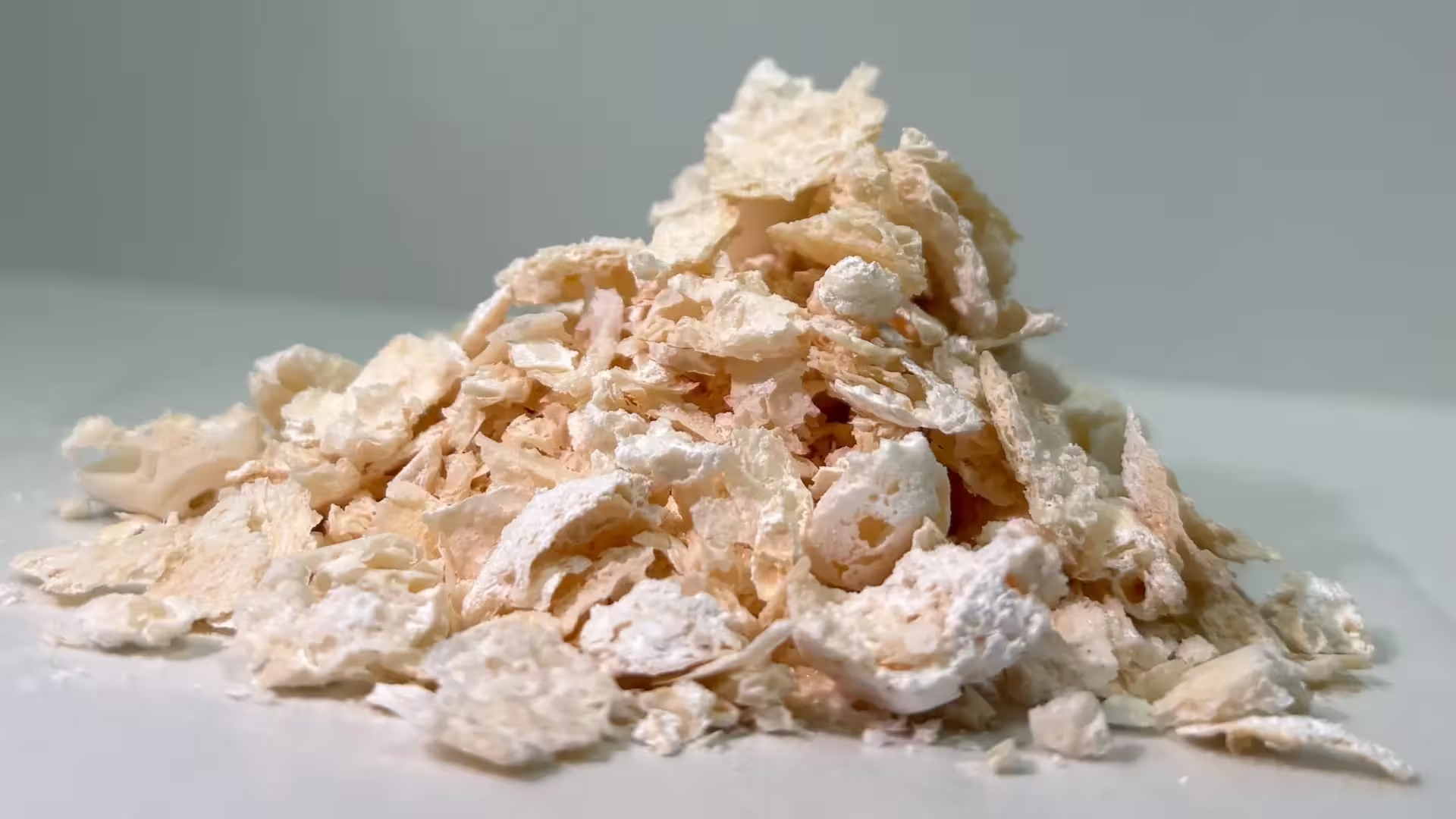

A team of bioengineers at Kobe University has reported a major advance in the microbial production of PDCA (pyridinedicarboxylic acid), a biodegradable monomer whose polymers show mechanical properties comparable to — and in some measures exceeding — those of conventional polyethylene terephthalate (PET). By reprogramming Escherichia coli metabolism, the researchers produced PDCA from glucose in stirred-tank bioreactors at concentrations more than seven times higher than previous reports, and they did so while avoiding the generation of toxic chemical byproducts that commonly plague hybrid chemical/biological routes.

PDCA is a promising candidate for high-performance, bio-based plastics used in containers, fibers and films. Unlike many biomass-derived molecules that contain only carbon, hydrogen and oxygen, PDCA requires the incorporation of nitrogen into the aromatic scaffold — a capability that has previously been difficult to achieve efficiently in microbial systems. The Kobe group focused on harnessing cellular nitrogen metabolism so the entire PDCA molecule could be assembled biologically rather than via partial chemical synthesis.

Scientific background and experimental approach

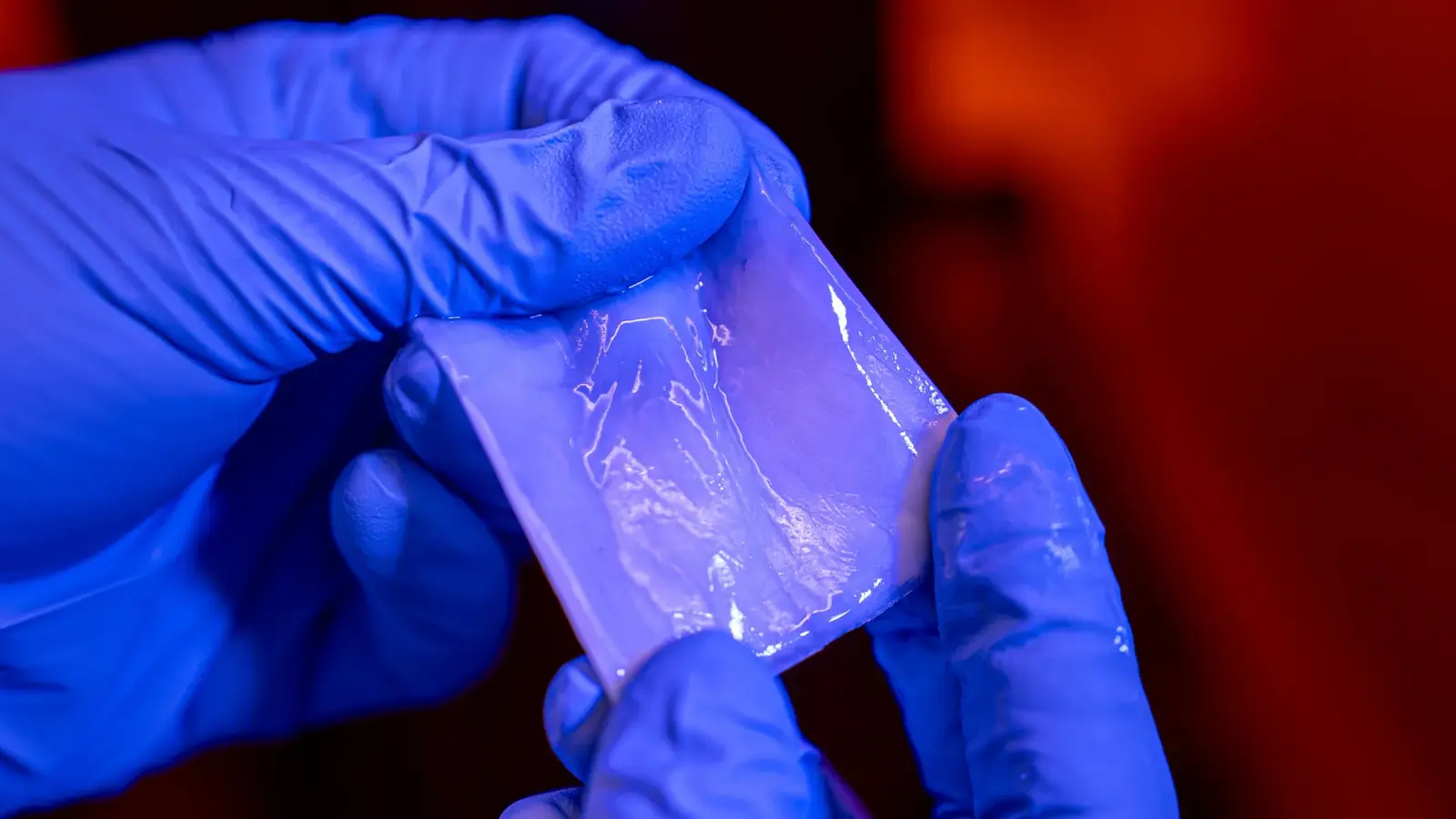

Engineering microbes to make complex monomers typically involves introducing non-native enzymes, optimizing metabolic flux, and balancing cofactor and precursor supply. The Kobe University team inserted enzyme combinations that channel glucose-derived carbon and assimilated nitrogen into the pyridine ring and carboxylate groups of PDCA. They optimized fermentation conditions in bench-scale bioreactors and tracked product yield, byproduct formation, and enzyme stability.

A key technical achievement was the elimination of unwanted side-products commonly formed in chemo-enzymatic routes. The researchers demonstrate that a fully biological pathway can incorporate nitrogen cleanly, enabling a purer final product and simplifying downstream purification. In their paper in Metabolic Engineering, the authors report PDCA titers that exceed prior microbial reports by more than seven-fold — a meaningful step toward industrial relevance.

Technical challenges and solutions

One persistent bottleneck the team encountered involved a heterologous enzyme that produced hydrogen peroxide (H2O2) as a side reaction. H2O2 is highly reactive and damaged the enzyme itself, creating a negative feedback loop that limited PDCA synthesis. The group reduced this problem by refining culture conditions and adding a peroxide-scavenging compound to the medium, which protected the enzyme and restored flux to the PDCA pathway. The team acknowledges that adding scavengers raises questions about cost and logistics for scale-up, and they propose genetic or process engineering fixes to remove the need for exogenous additives.

Key discoveries, implications and next steps

This work provides three important advances for bio-based plastics research: (1) demonstration that microbes can assemble nitrogen-containing aromatic monomers, (2) a significant increase in PDCA titer in bioreactors, and (3) practical troubleshooting of enzyme instability caused by reactive oxygen species. Together these points expand the portfolio of molecules accessible to microbial fermentation and move PDCA closer to commercial consideration as an alternative to petrochemical-derived PET.

The authors describe several paths to further improvement: engineering peroxide-tolerant enzyme variants, integrating intracellular peroxide-degradation systems, and optimizing feedstock-to-product yields. On the industrial side, techno-economic analysis and life-cycle assessment will be needed to compare PDCA-based polymers with existing materials, taking into account feedstock sourcing (glucose from biomass), energy use, and end-of-life biodegradability.

Expert Insight

Dr. Maya Ortega, a materials scientist specializing in sustainable polymers, comments: "This work is an important proof-of-concept. Achieving high PDCA titers in bioreactors addresses a common bottleneck — scale. The remaining challenges are typical: enzyme robustness and cost-competitive downstream processing. If those can be solved, PDCA-based polymers could enter markets where mechanical performance and biodegradability are both required."

Beyond packaging and textiles, nitrogen-containing monomers like PDCA could enable new classes of functional materials with tailored thermal and barrier properties, potentially impacting sectors from consumer goods to aerospace where performance per weight matters.

Conclusion

Kobe University's demonstration of high-yield, clean microbial synthesis of PDCA marks a notable step toward sustainable, high-performance plastics. By integrating nitrogen metabolism into a complete biosynthetic pathway and solving enzyme instability caused by hydrogen peroxide, the research opens new routes for bio-manufacturing aromatic monomers. Remaining work will focus on eliminating the need for chemical scavengers, improving yields further, and validating economic and environmental benefits at scale. If successful, PDCA could offer industry a renewable, biodegradable alternative to PET for containers, fibers and specialty materials.

Source: sciencedaily

Leave a Comment