6 Minutes

From Plastic Pollution to Carbon Capture

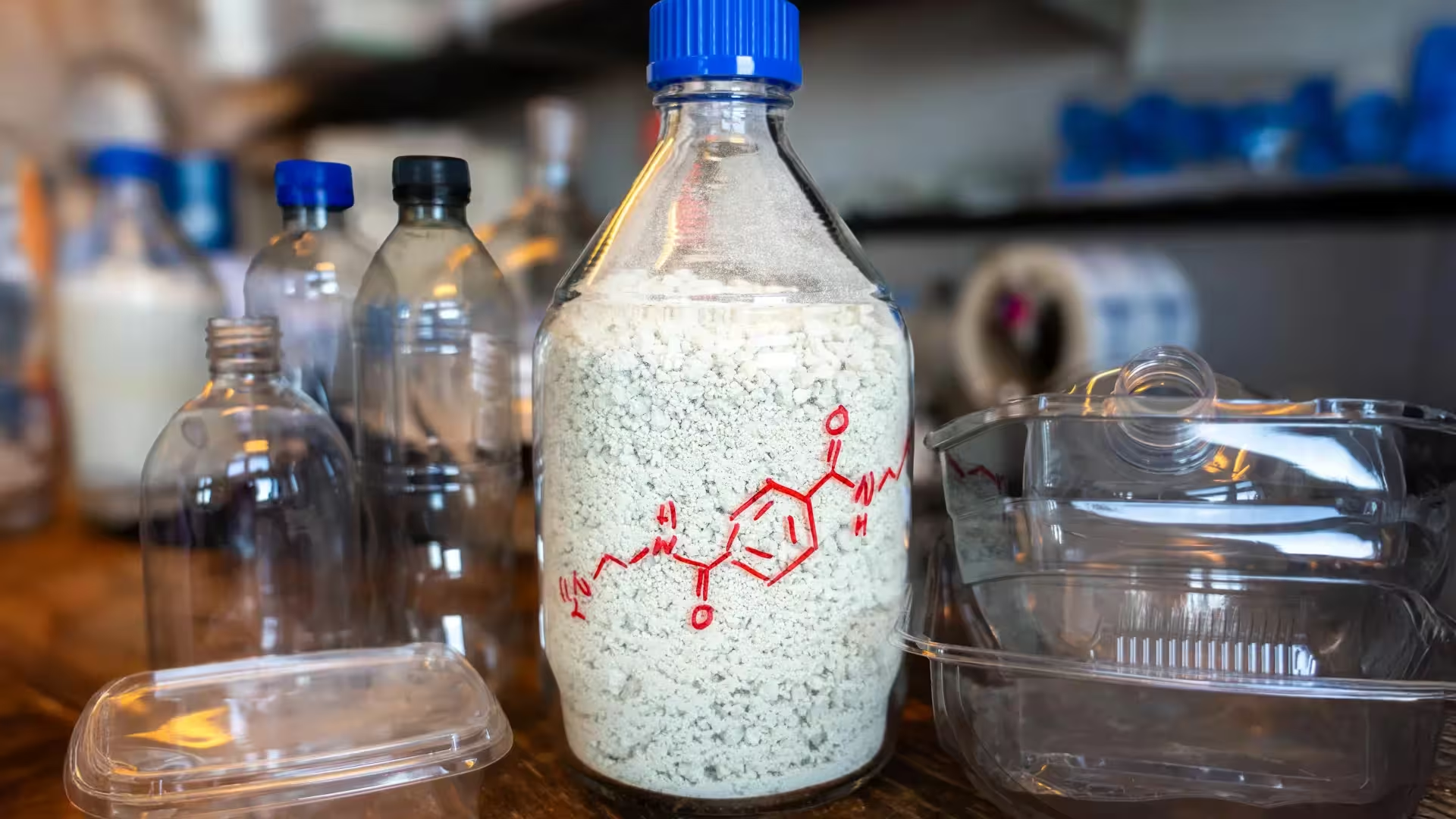

Chemists at the University of Copenhagen have developed a chemical upcycling process that converts discarded PET (polyethylene terephthalate) — the polymer used in bottles, textiles and packaging — into a new CO2 sorbent named BAETA. The approach repurposes low-quality or degraded PET that is difficult to recycle and transforms it into a powdery material with an engineered surface capable of chemically binding carbon dioxide. The result addresses two interconnected environmental crises: persistent plastic pollution and rising atmospheric CO2.

The University of Copenhagen team reports that the BAETA material captures CO2 with efficiency comparable to established carbon capture materials while using milder chemical conditions and a process that is amenable to scale-up. Instead of allowing PET to fragment into microplastics in soils and oceans, this method makes such waste feedstock for industrial carbon-management technologies.

Chemistry and mechanism: how PET becomes a CO2 sorbent

At the chemical level, PET is rich in carbon by weight and retains structural features that can be reworked into functional sorbents. The researchers break down the PET polymer to smaller units and functionalize the material with ethylenediamine, an amine compound well known for its strong affinity for CO2. Amine groups react with CO2 to form carbamates or related species, enabling chemical capture rather than mere physical adsorption. The BAETA material is therefore a chemically active sorbent: it binds CO2 effectively and, importantly, releases it when heated so the sorbent can be regenerated.

The synthesis is reported to proceed under relatively gentle conditions, including ambient temperatures during the key transformation steps, which reduces energy input compared with some solvent-intensive or high-temperature processes. The end product is a pelletizable powder that can be engineered into modular units for industrial exhaust treatment or other capture applications.

Performance, durability and industrial integration

University researchers report that BAETA retains capture capacity over many cycles and tolerates a broad temperature range — effective from near room temperature up to roughly 150°C. That thermal tolerance makes it suitable for deployment at the tail end of industrial chimneys and exhaust streams, where flue gases are still warm.

When BAETA becomes saturated with CO2, thermal desorption — a controlled heating step — releases concentrated CO2 for capture and storage or for conversion into value-added products via Power-to-X processes. The team envisions early adoption in on-site industrial carbon capture units that route exhaust through BAETA-filled modules to strip CO2 before emissions reach the atmosphere.

Scalability and economic outlook

The process targets PET waste that is not economical to recycle — discolored, contaminated or highly degraded plastic that currently accumulates in landfills and oceans. By using that low-value feedstock, the technology could create an economic incentive to collect polluted plastics. The researchers are pursuing scale-up to produce BAETA in tonne-scale batches and are seeking investment to move from laboratory demonstrations to commercial pilot plants. Because the transformation can proceed under mild conditions, the pathway to industrial scaling is technically straightforward compared with energy-intensive sorbent manufacturing.

Environmental implications and recycling compatibility

The method is designed to complement, not replace, conventional recycling. BAETA production prioritizes PET streams that are unsuitable for mechanical recycling, avoiding competition with high-quality recycling streams for food-grade or reusable plastics. Converting ocean-sourced and degraded PET into a material that removes CO2 could both reduce the microplastic burden in marine systems and provide a climate mitigation service.

The team also highlights the dual benefit: cleaning plastic pollution from natural environments and providing a route to capture and concentrate CO2 for storage or utilization. If broadly adopted, this approach could alter the economics of plastic cleanup by attaching direct climate value to recovered waste.

Expert Insight Dr. Anika Sharma, chemical engineer and carbon-capture specialist, comments: "Transforming low-value PET into a chemically active sorbent is a clever example of circular chemical engineering. The key metrics to watch as the technology scales will be the energy required for regeneration, the sorbent lifetime under real flue-gas conditions, and the cost of feedstock collection. If those align, BAETA could bridge waste-management and carbon-capture markets effectively."

Next steps and research priorities

The authors emphasize that the immediate technical work is scaling production, validating long-term cycling under industrial gas compositions (including moisture and common contaminants), and integrating BAETA modules with existing exhaust systems. Policy and investment decisions will be decisive: adoption requires capital for pilot installations and regulatory frameworks that recognize carbon removal carried out with upcycled materials.

Conclusion

Converting problematic PET waste into BAETA demonstrates a promising pathway to simultaneously address plastic pollution and carbon removal. The chemistry — breaking down polymer chains and functionalizing the material with amine groups — yields a regenerable sorbent that tolerates elevated exhaust temperatures and can be produced under mild conditions. If scaled and deployed at industrial sources, the technology could provide both environmental cleanup of degraded plastics and an effective, potentially low-cost route for CO2 capture and utilization, creating a tangible circular-economy model for two pressing global challenges.

Source: sciencedaily

Leave a Comment