6 Minutes

Micrometer-scale gears powered by laser light

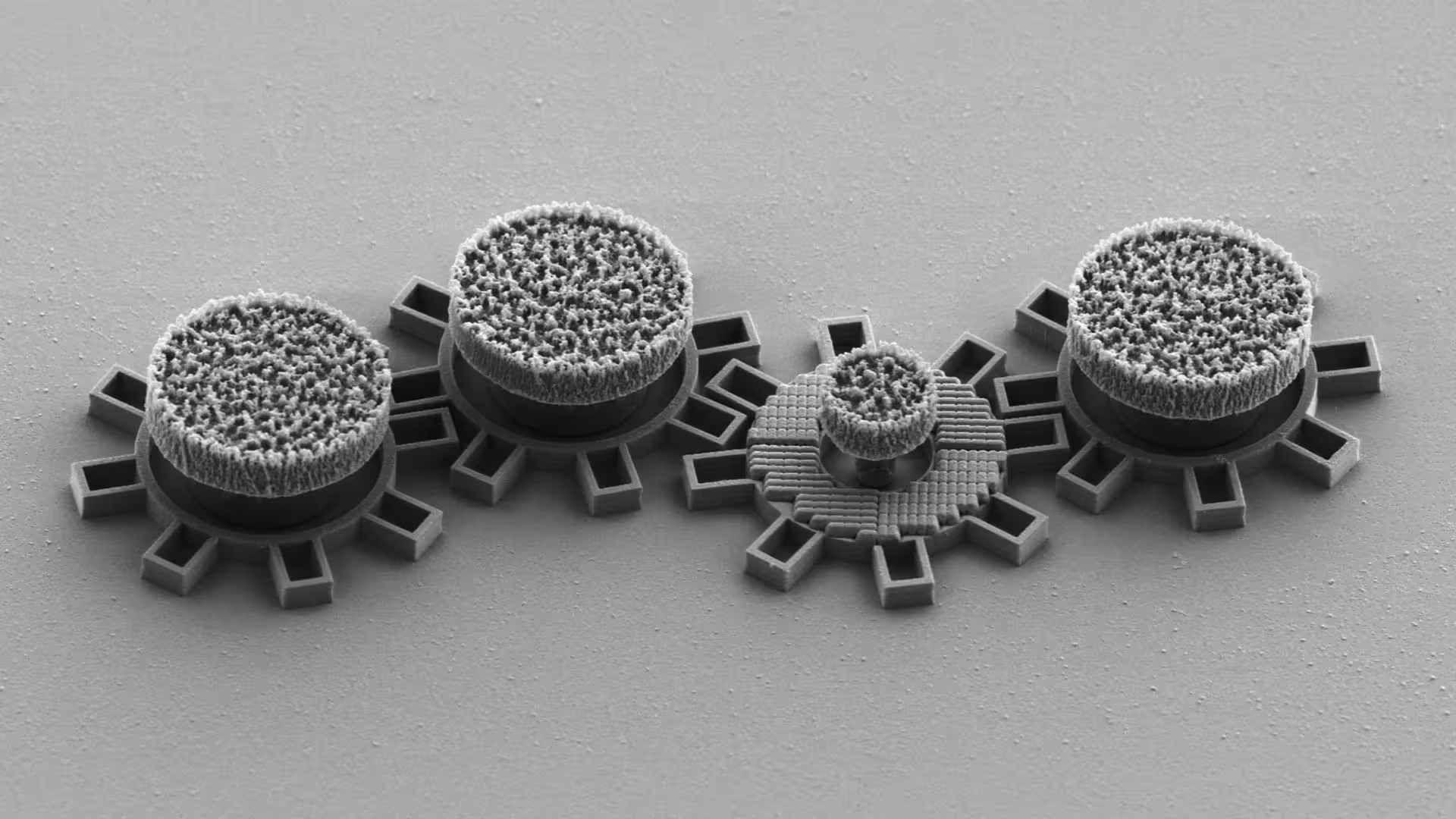

The University of Gothenburg has reported a breakthrough in microscale mechanics: researchers have fabricated light-driven gear wheels small enough to fit inside a human hair. By replacing conventional mechanical couplings with optical actuation, the team produced silica gears on a chip with diameters of only a few tens of micrometers and demonstrated controlled rotation, direction reversal and mechanical work at that scale.

The third gear from the right has an optical metamaterial that react to laserlight and makes the gear move. All gears are made in silica directly on a chip. Each gear is about 0.016 mm in diameter. Credit: Gan Wang

These micro-gears are built with standard lithography and incorporate patterned optical metamaterials—nanoscale structures that capture and manipulate incident laser light. When illuminated, the metamaterial converts light into localized forces and torques that turn the wheel. Varying the laser intensity changes rotational speed; altering polarization changes direction. This contact-free method eliminates the need for conventional mechanical drive trains, a longstanding barrier to making motors much smaller than 0.1 mm.

How the light-actuated micromotors work

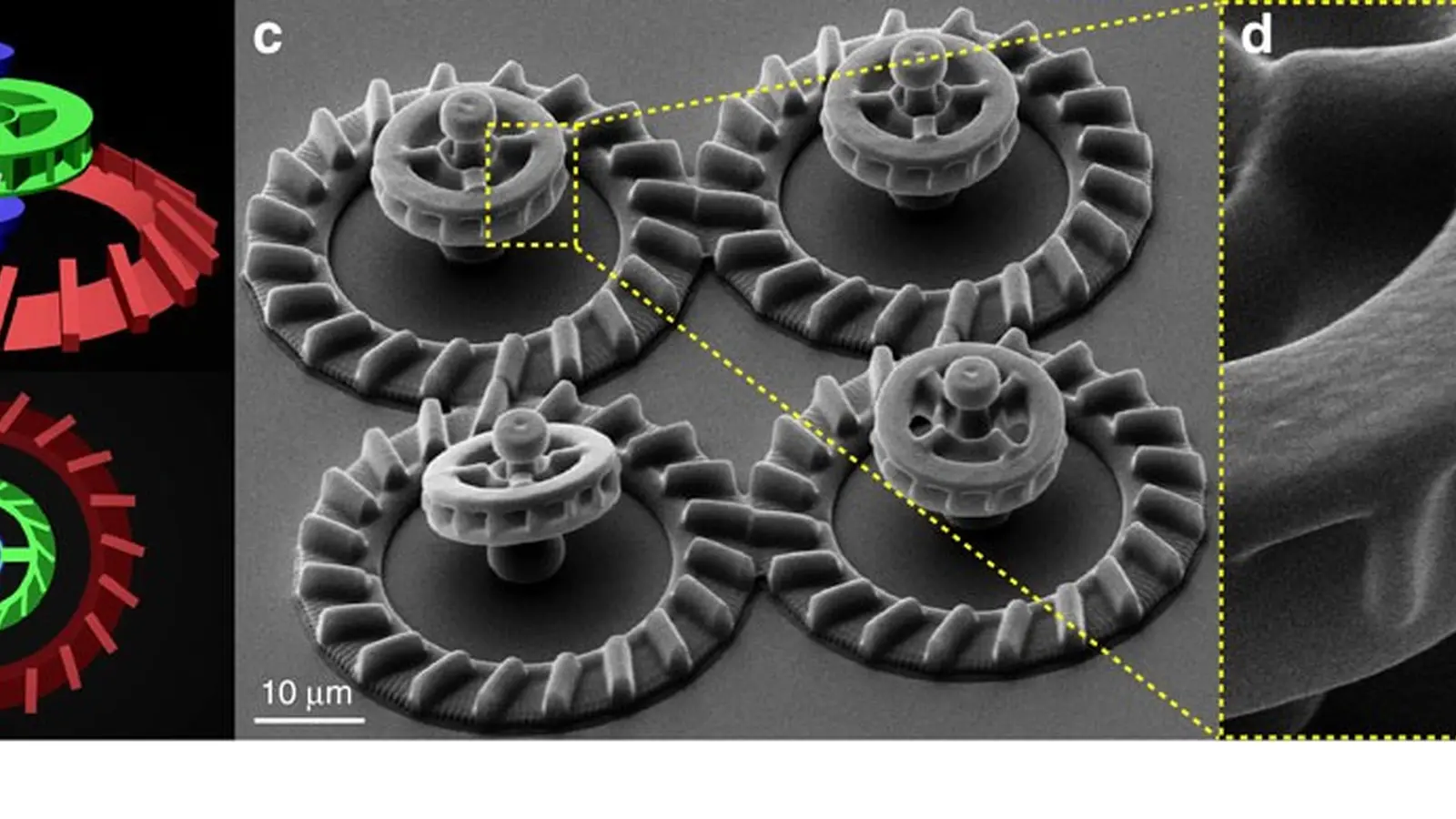

Optical metamaterials are engineered arrays of subwavelength features that modify light’s momentum and field distribution. In the Gothenburg devices, these patterns are integrated into a silica gear fabricated directly on a silicon chip. When a focused laser beam strikes the metamaterial patch, it produces asymmetric scattering and near-field forces that generate torque on the wheel. By tailoring the metamaterial geometry and the laser parameters (intensity, polarization, beam position), researchers can tune rotation rate, direction and coupling to neighboring mechanical elements.

Because the actuation is optical rather than mechanical, the driving signal is delivered without physical contact. That simplifies design and enables dense on-chip assembly: a single light-driven gear can set adjacent gears or linked components into motion. The team also demonstrated conversion of rotation to linear motion and periodic micromechanical movements, and showed that the gears can steer microscopic mirrors to redirect light locally—useful for integrated photonics and sensing.

Scientific context and implications for microdevices

Micro- and nanomachines have been an active research area for decades, with applications ranging from microfluidic pumps to lab-on-a-chip systems and targeted biomedical devices. The new approach addresses a key scaling limitation: traditional gear trains need space for axles, bearings and couplings, which become impractical below certain sizes. Optical actuation replaces bulky couplings with beams of light, enabling motors with feature sizes comparable to individual human cells (roughly 16–20 µm) and opening design space for complex microsystems.

Potential applications include optical switches and modulators on photonic chips, particle manipulation in microfluidics, and implantable or injectable microdevices for medicine. The researchers specifically highlight medical roles such as microscale pumps or valves that regulate fluid flows inside tissues or lab-on-a-chip diagnostic platforms that require integrated mechanical control.

Experiment details and fabrication

The devices were manufactured using established lithographic methods to pattern silica and silicon layers on a chip. The metamaterial patches are defined at the nanoscale to produce the desired optical response when illuminated by a visible or near-infrared laser. In experiments, the team adjusted laser power and polarization to demonstrate controlled start/stop, speed modulation and reversal of gear rotation. The chips were observed under microscopy to verify mechanical coupling between gears and to measure response times and torque estimates.

This work leverages cross-disciplinary techniques from soft-matter physics, nanofabrication and photonics, and points to scalable integration with existing semiconductor processes.

Expert Insight

Dr. Elena Márquez, a microfluidics engineer at a biomedical research institute (not involved in the study), says: "Replacing mechanical couplings with optical control is a clever way to overcome the physical limits of miniature gears. For medical microdevices, the ability to drive pumps or valves remotely with light could simplify implantation and control. Key next steps will be assessing biocompatibility, power delivery in tissue and long-term reliability."

Key discoveries and future prospects

The main achievement is demonstrating reliable, reversible, and controllable rotation of micrometer-scale gears driven solely by light, and integrating those gears on-chip with potential for mechanical linkage to neighboring components. Future research directions include optimizing metamaterial designs for higher torque, expanding functionality to nanoscale components, combining optical actuation with electrical or chemical sensing, and validating performance in biologically relevant environments.

While challenges remain—delivering laser power in vivo, ensuring robust operation in fluidic or biological media, and integrating readout electronics—the approach offers a pathway to truly microscopic machines that could operate at the scale of single cells.

Conclusion

Light-driven micromotors built from silica gears with integrated optical metamaterials represent a significant step toward functional microscale machinery. By exploiting laser light for contact-free actuation, researchers have overcome a major size barrier for gear-driven systems and opened new avenues for lab-on-a-chip technologies, integrated photonics, and potential biomedical devices such as micro-pumps and valves. Continued development of metamaterial geometries, power-delivery strategies and biocompatible packaging will determine how soon these micromotors move from laboratory demonstrations to practical applications.

Source: sciencedaily

Leave a Comment