6 Minutes

Transparent coating converts ordinary glass into solar-generating windows

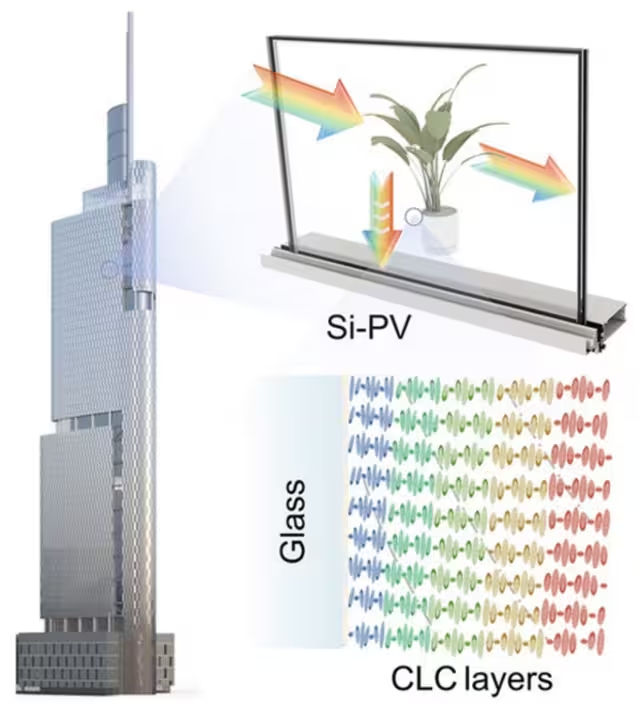

Scientists at Nanjing University have developed a transparent surface layer that can be applied to conventional window glass to harvest sunlight and route it to edge-mounted photovoltaic (PV) cells. The material—described by the researchers as a colorless and unidirectional diffractive-type solar concentrator (CUSC)—preserves the visual clarity of windows while redirecting a portion of incoming sunlight so it can be converted to electricity.

The research team has produced a small functional prototype and published their results in PhotoniX. If the coating can be manufactured and scaled affordably, retrofitting existing building glazing and new windows could add significant distributed renewable generation capacity across urban areas, contributing to building-integrated photovoltaics (BIPV) and broader decarbonization goals.

How the CUSC works: cholesteric liquid crystals and selective light steering

At the core of the coating are cholesteric liquid crystals (CLCs), a class of materials with engineered helical molecular structures that interact with light in wavelength- and polarization-dependent ways. By stacking multiple CLC layers tuned to different bands of the solar spectrum, the coating covers a wide range of visible wavelengths while remaining visually transparent.

Polarization-selective diffraction

A key design feature is that the CUSC selectively diffracts one circular polarization of light. That means only photons with a specific polarization state are redirected laterally into the glass, where they are guided by total internal reflection toward PV cells mounted at the window edges. Light of other polarizations largely passes through the pane, preserving typical window function and daylighting.

Optical engineer Dewei Zhang, a coauthor of the study, explains that by engineering the internal structure of the CLC films the team can ‘‘selectively diffract circularly polarized light, guiding it into the glass waveguide at steep angles.’’ This waveguide effect concentrates light onto edge-mounted cells without introducing strong coloration.

The authors refer to the finished device as a colorless and unidirectional diffractive-type solar concentrator (CUSC), which emphasizes both its visual neutrality and its one-way light-steering behavior toward energy conversion hardware.

Performance metrics, prototypes, and limitations

In laboratory tests the coating demonstrated promising optical performance: it transmits 64.2 percent of visible light and preserves 91.3 percent color accuracy, important metrics for user comfort in buildings. Using a green laser—chosen because the human eye is most sensitive in that region—the device captured and converted 38.1 percent of the incident energy, indicating a high theoretical capture efficiency under idealized conditions. In broader tests with polychromatic light that mimics real solar illumination, the researchers report an optical collection efficiency of 18.1 percent.

The team fabricated a 1-inch prototype panel coated with the CUSC that generated enough power to run a small fan. However, the current overall power conversion efficiency—the fraction of incoming solar energy that is transformed into usable electric power when the full optical path and PV conversion are considered—remains low at about 3.7 percent. That number reflects losses in light steering, waveguide transport, and the edge-mounted PV conversion chain.

"The CUSC design is a step forward in integrating solar technology into the built environment without sacrificing aesthetics," said optical engineer Wei Hu, a member of the research team. "It represents a practical and scalable strategy for carbon reduction and energy self-sufficiency." Still, the authors note that improving stability, manufacturing reproducibility, and power conversion efficiency will be essential before commercial deployment.

Challenges to scaling and routes to improvement

Several technical and manufacturing hurdles must be addressed to move from prototype to market-ready product. The researchers highlight the need to:

- Increase the device-level electrical conversion efficiency by optimizing edge PV cell placement, reducing waveguide losses, and improving the spectral coverage of the stacked CLC layers.

- Enhance the environmental and mechanical stability of the liquid crystal films so the coating withstands UV exposure, temperature cycles, and routine maintenance for building glazing.

- Develop scalable deposition or lamination techniques compatible with large-area glass and existing window-manufacturing processes to meet cost and throughput targets.

"To scale up production, several improvements in materials and procedures need to be considered," the team writes in their published paper, noting that industrial adoption will depend on balancing optical performance, durability, and cost.

Related technologies and potential applications

Transparent or semi-transparent photovoltaics are an active area of research within building-integrated photovoltaics and urban photovoltaics. Alternatives include thin-film BIPV modules, organic photovoltaics integrated into glazing, and luminescent solar concentrators (LSCs) that absorb light and re-emit it toward edges. The CUSC differs from many of these approaches by combining high visible transparency, color neutrality, and directional light steering through polarization-selective diffraction.

Practical applications range from retrofitting office and residential windows to incorporating the coating into skylights, greenhouse glazing, vehicle glass, and even solar-augmented display screens. If widely deployed, window-based generation could supplement rooftop and ground-mounted solar arrays and provide distributed energy close to building loads.

Expert Insight

Dr. Lena Martínez, a photovoltaics researcher and lecturer in applied optics, comments: "The Nanjing team demonstrates an elegant optical approach using cholesteric liquid crystals to preserve transparency while directing energy to PV cells. The reported numbers are encouraging for lab-scale devices, but the critical challenge will be converting optical promise into economically viable, durable products. Improvements in module-level efficiency and long-term stability will determine whether this becomes a mainstream building-integrated solution."

This perspective echoes the consensus among building-integrated photovoltaics researchers that material durability, manufacturing cost, and integration with existing glazing standards are as important as laboratory efficiency figures.

Conclusion

The colorless and unidirectional diffractive-type solar concentrator (CUSC) developed by Nanjing University researchers demonstrates a promising path toward truly transparent solar windows. Using stacked cholesteric liquid crystal films to selectively diffract circularly polarized light, the coating can steer a portion of sunlight to edge-mounted PV cells while allowing most visible light to pass through. Early prototypes show useful optical transparency and measurable power output, but the current device-level electrical conversion efficiency (about 3.7 percent) and manufacturing challenges mean further materials research and engineering development are required. If those hurdles can be overcome, transparent solar coatings could become a significant component of building-integrated renewable energy, adding distributed generation capacity without altering window aesthetics.

Source: sciencealert

Leave a Comment