3 Minutes

CATL has quietly shifted humanoid robots from demo stages into real factory work, rolling out its Moz robot across a battery pack line. This move signals that embodied intelligence may finally be ready for quality-critical roles in EV production.

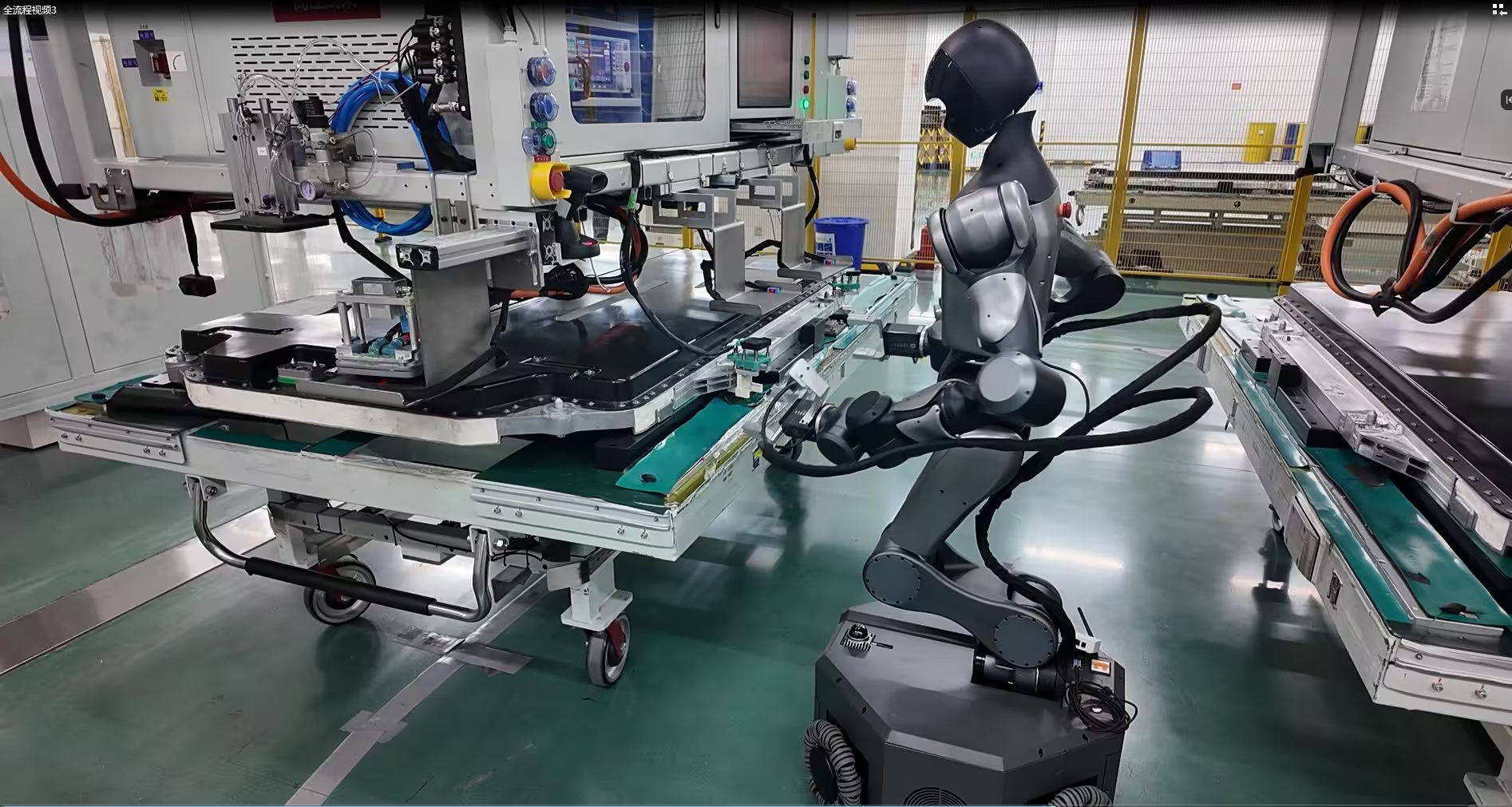

Moz steps onto the production line — not just for show

The humanoid, called Moz, was developed by Spirit AI, a robotics arm of CATL. Unlike many headline-grabbing demos, CATL says it completed a large-scale deployment of Moz at a power battery plant, making it one of the first production lines to use humanoid "embodied intelligence" robots at scale.

Rather than being limited to simple pick-and-place tasks, Moz is stationed at stages of the process where precision and reliability are non-negotiable. That represents a meaningful shift — from proof-of-concept stunts to machines doing work that affects product quality and revenue.

Precision where it matters: connector insertion and adaptive vision

Moz's main assignment is attaching battery connectors, a deceptively demanding job that requires exact alignment, consistent motion, and careful control of applied force. CATL reports that Moz hits a 99% success rate on connector insertion, performance the company says rivals experienced human operators.

That accuracy isn’t luck. Moz combines an end-to-end vision system with real-time posture adjustments and force monitoring. If materials are slightly misaligned or a connection point shifts, the robot adapts on the fly — changing its orientation and grip and modulating pressure to secure wiring harnesses without damaging delicate components.

- End-to-end vision: detects parts and compensates for variance.

- Force sensing: ensures firm, safe connections without breakage.

- Adaptive control: reacts dynamically rather than following rigid paths.

How Moz compares to other humanoid trials

Reports of other humanoid robots struggling during factory trials — from overheating joints to failures in complex assemblies — have been common. Many of those systems attract attention through staged demos but fall short in continuous, demanding industrial environments.

CATL emphasizes Moz’s industrial readiness as a differentiator. The company’s approach appears focused on task-specific robustness rather than general-purpose theatrics, prioritizing long-term uptime and repeatable quality over viral moments.

Why this matters for the robotics and EV industries

China’s humanoid robotics sector is expanding fast, with analysts warning of potential overcapacity reminiscent of rapid EV manufacturing growth. Still, CATL’s deployment shows humanoid robots can be more than experimental showpieces — they can be practical tools that contribute to production metrics and reduce variability in quality-critical operations.

For manufacturers, this raises practical questions: will humanoid platforms scale economically across different tasks, and can developers keep improving durability and uptime? For investors and planners, CATL’s example suggests a path where robotics investment ties directly to factory performance and revenue.

Imagine a future factory where humanoid robots handle the trickiest assembly steps while collaborating with humans on inspection and oversight. CATL’s Moz doesn’t answer every question, but it’s a concrete step toward that scenario — and an early signal that humanoid automation is moving from spectacle to the shop floor.

Source: gizmochina

Leave a Comment