6 Minutes

Hyundai's robotics play takes center stage at CES 2026

Hyundai used CES 2026 in Las Vegas to lay out an ambitious roadmap that could reshape automotive factories and logistics worldwide. The South Korean automaker presented a coordinated strategy to mass-produce humanoid robots and integrate them into its manufacturing network, declaring a bet on what it calls "real-world human-centered AI robotics." For car enthusiasts and industry watchers, the move signals a new chapter in automotive production, where physical AI and robotics move from pilot projects to mainstream factory floor partners.

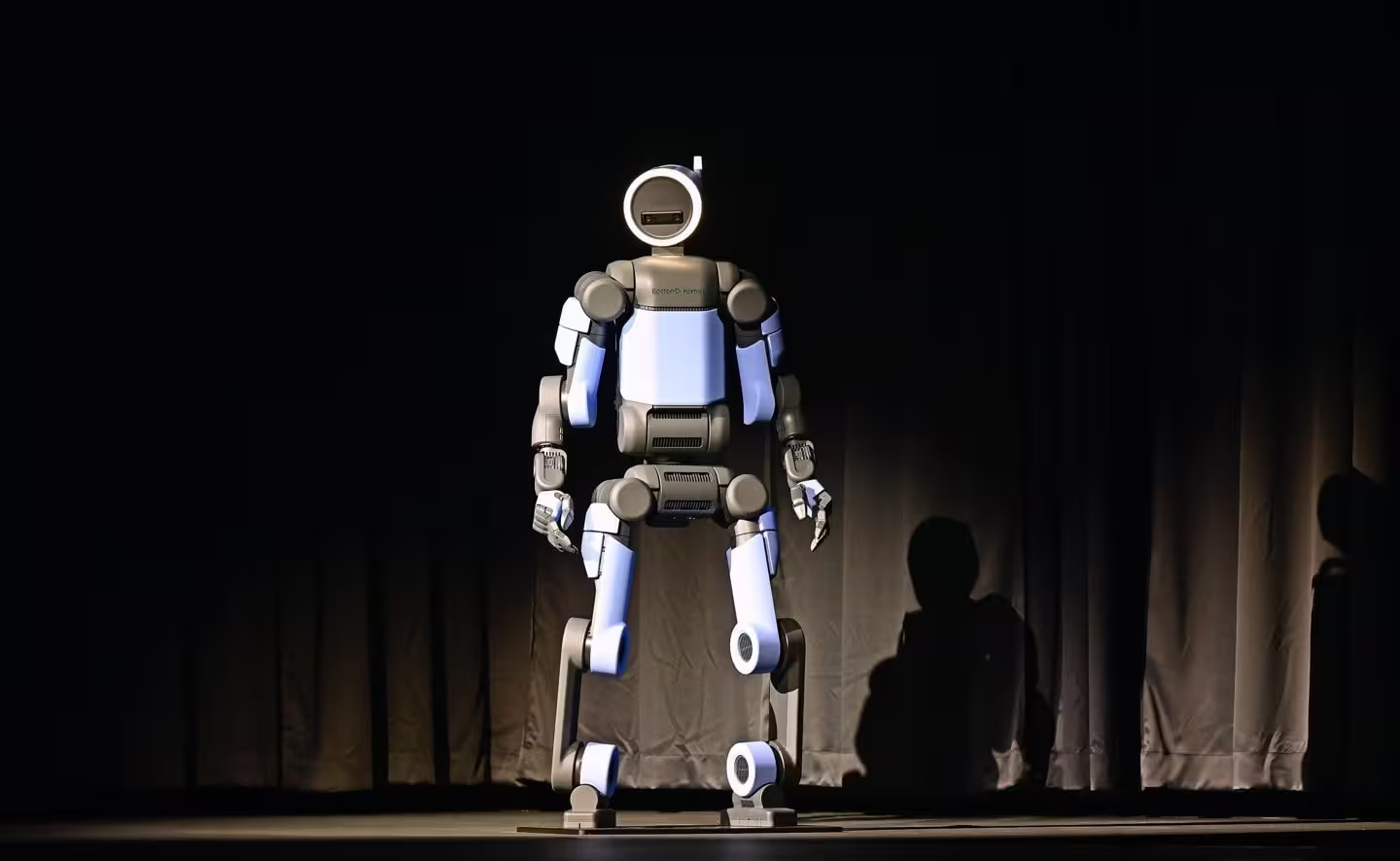

From concept to production: Atlas at the heart of the plan

At the center of Hyundai's initiative is the Boston Dynamics Atlas humanoid — a bipedal robot platform whose lineage dates back to 2013. Boston Dynamics, acquired by Hyundai in 2021, showcased an updated Atlas at CES; Hyundai plans to transition the robot from a development demonstrator to an industrial workhorse.

Rather than creating household helpers, Hyundai envisions Atlas as a specialist for industrial tasks. The plan is phased: initial deployments will focus on clearly demonstrable safety and quality gains, followed by broader use in assembly, repetitive operations, and heavy-load transport across production lines.

Highlights of the announced timeline:

- 2026–2027: Extensive training and validation inside Hyundai Group facilities.

- 2028: Introduction of Atlas for parts sequencing and processes with proven safety/quality benefits, including at Hyundai Motor Group Metaplant America (HMGMA) in Savannah, Georgia.

- 2030 and beyond: Expanded roles in component assembly, repetitive tasks, and on-floor logistics.

This staged approach underscores an automotive-first mindset: Hyundai will pilot Atlas across its own plants — including those operated under the Kia brand — before a wider roll-out.

AI partnerships and the drive for rapid capability gains

A key component of Hyundai's strategy is integrating advanced AI models into robot development and operations. The company announced plans to leverage Google DeepMind technology alongside Boston Dynamics' robotics expertise. While Hyundai has not detailed the full technical integration, executives say the convergence of robotics and large-scale AI will accelerate learning, safety, and adaptability on the factory floor.

As Zachary Jackowski, Boston Dynamics' Atlas lead, put it at CES, the collaboration aims to redefine industry paradigms by combining robotics hardware with cutting-edge artificial intelligence — a claim that points toward more autonomous decision-making and faster onboarding of robotic workers.

Beyond Atlas: a fleet of purpose-built machines

Hyundai’s CES booth made it clear this effort is broader than a single humanoid. The company displayed several Boston Dynamics platforms and Hyundai-developed robotics to show how physical AI can be applied across automotive operations:

- Spot: The agile quadruped already deployed in over 40 countries for data collection and site safety.

- Stretch: A warehouse robot designed to handle repetitive loading and unloading of boxes — a direct efficiency play for logistics and parts distribution.

- MobED (Mobile Eccentric Droid): A wheeled robotic platform first revealed in 2022 that has evolved into a versatile carrier used for intra-facility shuttle tasks.

- Ioniq 5 Robotaxi and Parking Robot: Electric vehicle-based demos intended to showcase autonomous mobility, valet parking automation, and integration between vehicles and robotic systems.

These complementary platforms illustrate a systems approach: humanoids for assembly and complex manipulation, quadrupeds and wheeled bots for inspection and logistics, and autonomous EVs to bridge mobility gaps on-site.

Why this matters for the auto industry

Automotive manufacturing is intensely practical: cycle times, quality control, and ergonomics matter. Hyundai’s robotics blueprint directly targets these pain points. Humanoid robots can potentially:

- Reduce repetitive-strain injuries among line workers by taking on strenuous, repetitive motions.

- Improve process consistency in parts sequencing and assembly.

- Accelerate throughput in logistics-heavy operations such as metaplants and central distribution hubs.

From a market-position perspective, Hyundai aims to become the leader in "physical AI" — a term for robots that act in the physical world under intelligent control systems. If successful, that would not only cut costs and improve quality for Hyundai and Kia but could create a new industrial product line with export potential to other OEMs and tier suppliers.

Challenges and caveats

The roadmap is bold, but not without hurdles. Widespread factory adoption raises questions about:

- Safety certifications and standards for humanoids operating alongside human workers.

- The scale and quality of training data required to generalize Atlas' capabilities across diverse production tasks.

- Workforce transition and reskilling programs to manage the human-robot collaboration.

Hyundai’s phased timeline acknowledges those challenges by prioritizing demonstrated safety and quality improvements before full-scale deployment.

What to watch next

- Technical details on the Google DeepMind integration and what functions it will unlock for Atlas.

- Results from early trials at HMGMA in Savannah and other Hyundai/Kia plants.

- Production decisions: when Hyundai will start mass-producing Atlas and at what scale.

"The convergence of robotics and AI represents more than a technological advancement," Jackowski said — a succinct summary that doubles as a mission statement. For automotive fans, analysts, and supply-chain managers, Hyundai’s CES announcement signals that the next decade in auto production may look just as much like a robotics lab as a traditional factory.

Key takeaway: Hyundai is betting big on humanoid and mobile robotics to transform manufacturing and logistics. With Boston Dynamics hardware, planned AI partnerships, and pilot deployments across Hyundai Group facilities, the automaker wants to turn physical AI from a novelty into a core component of next-generation automotive production.

Source: autoevolution

Comments

labcore

Can they really train Atlas fast enough for diverse tasks? Seems optimistic, and who certifies safety, workforce impact... if that even pans out

mechbyte

Whoa, this actually feels like sci fi becoming boring real life... Atlas on the line? If they sort safety and retraining, huge win but yikes

Leave a Comment