5 Minutes

Microbial route to a more biodegradable plastic ingredient

Plastic is foundational to modern life but remains costly for the environment: its production is fossil-fuel intensive and much of it persists as pollution. Researchers at Kobe University in Japan report a substantial advance in producing pyridinedicarboxylic acid (PDCA), a nitrogen-containing monomer that can be incorporated into polyester plastics to increase biodegradability and reduce reliance on petroleum-derived terephthalic acid. Researchers have produced the plastic alternative in much larger quantities than before. (Tanaka Tsutomu)

PDCA is not a finished plastic product itself but an alternative building block for polymers such as PET (polyethylene terephthalate). Replacing nonbiodegradable monomers with PDCA enables manufacture of plastics that retain desirable mechanical properties while becoming easier to break down under appropriate conditions. Prior studies have flagged PDCA's potential; the new Kobe University work focuses on delivering PDCA at higher yields and with cleaner chemistry, key requirements for industrial adoption.

Metabolic engineering and process improvements

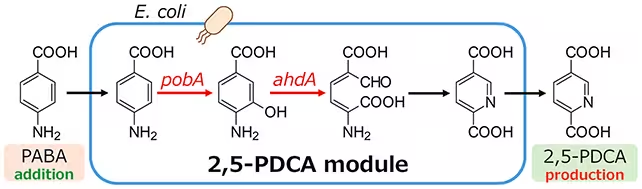

The team used engineered Escherichia coli cells supplied with glucose and outfitted with selected enzymes to channel metabolism toward PDCA.

PDCA was produced using E. coli and enzymes. (Katano et al., Metab. Eng., 2025)

Key technical changes

- Enzyme selection: The researchers introduced enzymes from nitrogen metabolism to enable the microbe to incorporate nitrogen directly into the growing aromatic ring, avoiding separate chemical aminating steps.

- Process optimisation: Refinements to culture conditions and reaction sequences raised PDCA yields to approximately seven times those reported with earlier methods.

- Byproduct control: Initial modifications produced a toxic byproduct related to hydrogen peroxide (H2O2) formation. The team resolved this by adding a pyruvate-based scavenger and adjusting culture parameters to neutralize H2O2 without creating additional contaminants.

These advances demonstrate that cellular metabolic reactions can perform nitrogen incorporation cleanly and efficiently, a significant step because many synthetic routes to nitrogen-containing monomers rely on hazardous reagents or generate toxic waste. According to lead bioengineer Tanaka Tsutomu, "Our group approached the challenge from a new angle. We aimed to harness cellular metabolism to assimilate nitrogen and build the compound from start to finish." He added that the work shows metabolic reactions can incorporate nitrogen without producing unwanted byproducts, enabling cleaner synthesis of target compounds.

Despite the gains in yield and purity, the authors caution that adding pyruvate or similar scavengers introduces economic and logistical considerations for large-scale production. Further scale-up work will need to weigh reagent costs, downstream purification, and reactor design against environmental benefits and product performance.

Implications, related materials and future prospects

PDCA’s improved microbial production moves it closer to commercial viability as a bio-based replacement ingredient for petroleum-derived monomers in polyester manufacturing. The compound can be generated from renewable feedstocks (e.g., glucose) in bioreactor systems, pointing to an integrated bio-manufacturing approach where feedstock, engineered microbes, and reactor conditions are co-optimised.

Related biomaterials are also emerging: bacterial cellulose combined with hexagonal boron nitride (BCBN) has been reported this year, demonstrating how microbial products can be structured for enhanced mechanical and thermal properties. Together, these developments show a broader trend in materials science toward biologically derived, high-performance alternatives that reduce dependence on fossil resources.

Scale-up challenges remain significant: process economics, reagent supply (including any H2O2 scavengers like pyruvate), regulatory approval for new polymer chemistries, and lifecycle analysis to confirm net environmental benefit. Still, the reported sevenfold increase in PDCA yield and the elimination of earlier toxic wastes are important milestones for industrial biotechnology and sustainable materials development.

Expert Insight

Dr. Mira Patel, materials scientist (fictional), comments: "This work is a pragmatic demonstration of how metabolic engineering can access monomers that were once the domain of petroleum chemistry. The practical hurdles—cost of scavengers, purification, and polymer testing—are real, but the biology-first approach narrows the gap between lab-scale sustainability and industrial reality. If PDCA-based polyesters prove compatible with existing recycling streams, their adoption could be accelerated."

Conclusion

The Kobe University team’s metabolic-engineering strategy substantially increases PDCA production while reducing toxic byproducts, advancing a bio-based route to more biodegradable polyester monomers. Although commercial scalability still requires resolving reagent costs, reactor design, and downstream processing, this research broadens the universe of molecules accessible through microbial synthesis and strengthens the case for bio-manufactured, lower-impact plastics.

Source: sciencealert

Leave a Comment