3 Minutes

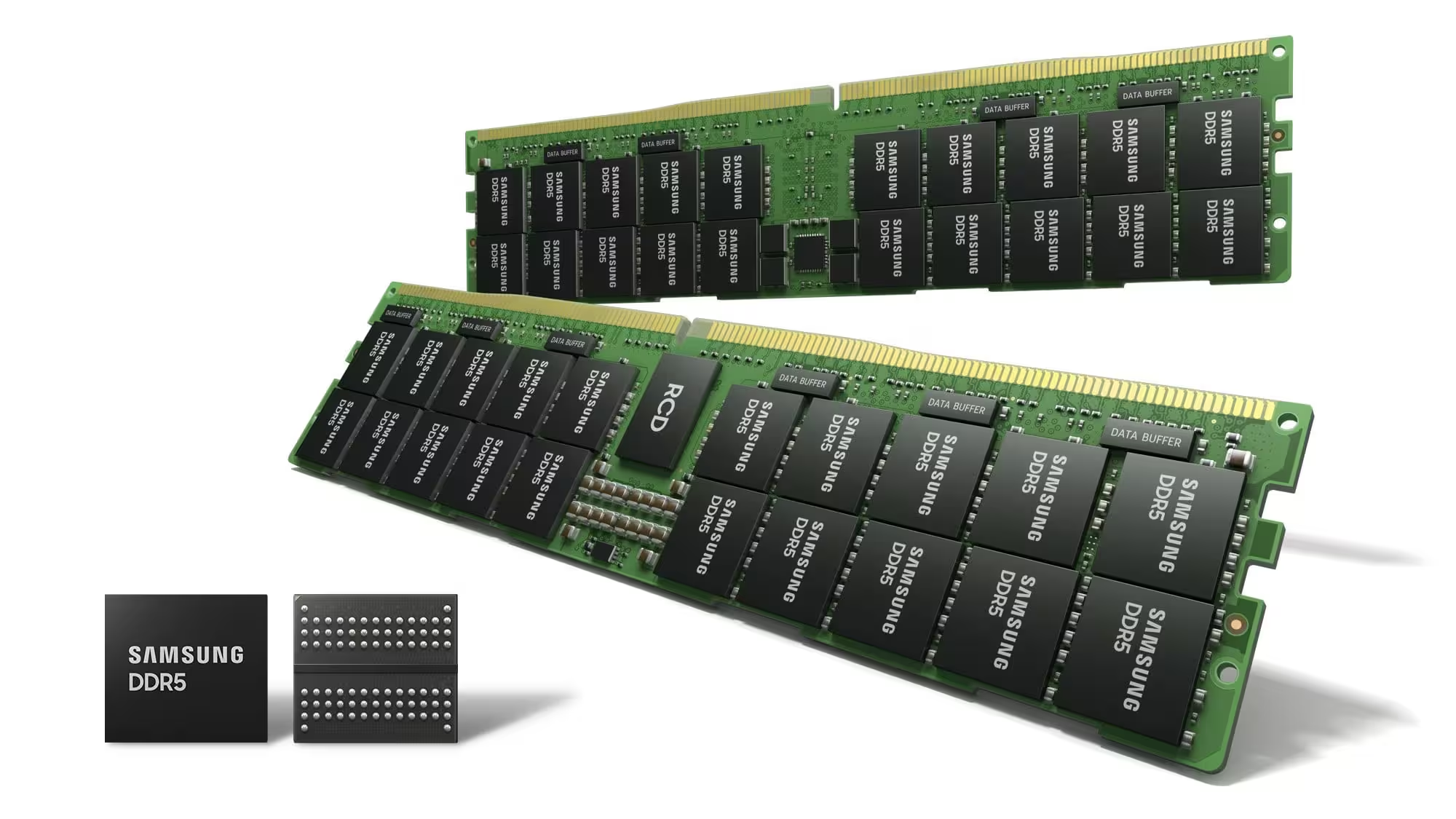

DDR5 memory prices are staying stubbornly high, and some PC builders aren’t waiting for the market to cool. With AI servers and data centers gobbling up supply, a small but determined group of hardware enthusiasts has started assembling DDR5 modules by hand — a risky, meticulous hobby born from frustration and necessity.

When server demand steals the consumer market

Industry analysts warn that tight DDR5 supply could persist into 2027 as enterprise demand for AI infrastructure continues to climb. That squeeze keeps retail prices elevated, putting routine upgrades out of reach for many DIY builders. So instead of watching their upgrade plans stall, a handful of modders are taking matters into their own hands.

The DIY DDR5 workflow — what it looks like

Building a DDR5 stick isn’t just hot‑swapping chips. Enthusiasts source blank DDR5 PCBs, buy individual memory ICs, and solder the components together. According to reports from Pro Hi‑Tech, pre‑designed DDR5 PCBs are available from Chinese suppliers, which lowers the technical barrier for experienced hobbyists. The trickier parts are precise soldering and rigorous validation to ensure the module runs stably at rated speeds.

Typical steps

- Order a pre‑designed DDR5 PCB and compatible memory ICs.

- Use fine‑pitch soldering techniques (hot air, reflow, or BGA rework) to place chips.

- Run memory validation tools and stress tests to check timings and stability.

- Tweak SPD/firmware if necessary and retest under load.

How the costs compare — and why some still save

Price-wise, the DIY route can be competitive. A homemade 16GB DDR5 stick is estimated at roughly 12,000 rubles — about $150. Branded retail modules like A‑Tech’s 16GB DDR5 5600MHz retail for around $190. That margin could grow if components drop in price or are purchased in bulk, making DIY attractive for a few who can guarantee reliable assembly.

Not for the faint of heart

This approach isn’t a recommendation for average users. It demands steady hands, access to testing gear, and patience for trial and error. There’s no warranty if a module fails, and a botched build can mean wasted components or worse. Expect intermittent instability unless you have the tools and expertise to validate and tune the module.

Who might try it?

Experienced hardware modders, repair technicians, and those comfortable with surface‑mount soldering and BGA rework are the primary candidates. For everyone else, the risks outweigh the potential savings.

What this trend says about the market

DIY DDR5 modules are more than a niche hobby — they’re a signal. When enthusiasts begin fabricating critical components, it underlines how constrained consumer supply has become and how strongly enterprise demand is reshaping the market. It’s a creative response to a pricing problem, but it also highlights the gap between enthusiast desire and retail availability.

Will DIY DDR5 ever go mainstream? Probably not. But for now, it’s a fascinating example of how far some builders will go to keep their rigs current while waiting for the wider market to normalize.

Source: gizmochina

Leave a Comment