5 Minutes

Buried in piles of discarded mining waste, there may be a hidden treasure that could ease pressure on global supply chains: rare earth elements. They’re not exotic in the astronomical sense, but within the finely ground leftovers of coal processing — the so-called coal tailings — lie metals essential to modern energy and electronics industries. How do we get them out? That’s the question a Northeastern University-led team set out to answer, and the results could reshape how we think about mining, recycling, and environmental remediation.

Rare earth elements (REEs) — think neodymium, dysprosium and others — are the backbone of high-strength magnets, electric vehicle motors, wind turbine generators, and compact electronics. They’re called "rare" more because of their geochemical behavior than scarcity: they tend to cling to clay minerals and other hosts, making extraction technically complex and often costly. Traditional methods struggle to pry these elements from the microscopic cages that hold them, which drives exploration toward new ore bodies and, increasingly, toward resource-intensive processing overseas.

How the new method works

The novel approach combines two steps that alter the mineral matrix binding the REEs. First, researchers soak the tailings in an alkaline solution. Then, while that pretreated material is heated using microwave energy, an acid digestion follows — a nitric acid wash that separates the freed rare earths from the remaining rock. The upshot: a porous, altered solid structure that's far more cooperative during chemical separation than the original, tightly bound clay.

Microwaves are not being used as a kitchen shortcut here; in the lab they deliver rapid, volumetric heating that changes mineral lattices more efficiently than conventional ovens. The alkaline pretreatment appears to pry open the crystal structures that trap REEs, and the microwave-assisted heating accelerates that transformation. After the acid step, recovery of elements such as neodymium is markedly improved. In this study, the team reports extraction yields up to three times higher than some current techniques.

The extraction process used in the study may be difficult to scale up, say the researchers.

That kind of improvement matters. Estimates suggest that in the United States alone, every 1.5 billion tons of coal tailings could hide more than 600 kilotons of recoverable REEs. Pennsylvania, for example, holds roughly two billion spare tons of such waste; across the country and the world, the volumes are vast. Turning a liability into a resource would reduce the need for new mines and diversify supply, a strategic advantage as demand for clean-energy technologies rises.

Scientific context and practical hurdles

Extracting REEs from tailings isn’t simply a chemical puzzle. It’s a materials problem. REEs are often adsorbed onto or locked inside fine-grained clay minerals and iron oxides. Pulling them free requires breaking bonds without creating new environmental hazards. The Northeastern-led method targets the mineral host: alkaline pretreatment loosens the grip, microwaves speed up reactions, and nitric acid separates the elements for further purification.

But the leap from bench to plant is nontrivial. Scaling microwave reactors for thousands of tons of material poses engineering and cost challenges. Mineralogy varies widely from one tailings pile to another, meaning a one-size-fits-all recipe is unlikely. In some locations, other valuable metals—magnesium, for instance—also exist in the waste and could be co-recovered, which would improve economics but complicate process design.

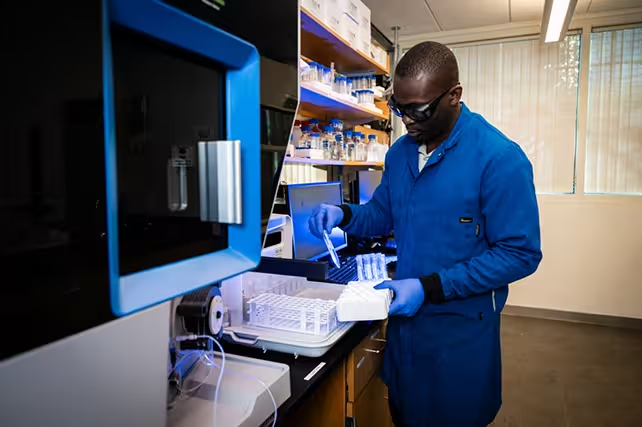

"What we're seeing is a change in the solid structure of this material," says Damilola Daramola, a chemical biologist at Northeastern University and a member of the research team, describing how the combined treatment creates porosity and releases locked-in elements. The statement underscores why this research is as much about materials engineering as it is about chemistry.

Environmental considerations are central. Reprocessing tailings could reduce the footprint of fresh mining, lower the transport of ores across oceans, and make existing waste storage safer by reducing reactive volumes. Yet careful lifecycle assessments are needed: energy inputs, reagent disposal, and potential secondary pollution must all be balanced against the benefits of recovered REEs.

Expert Insight

Dr. Lena Ortiz, a materials scientist who studies critical minerals, comments: "Innovations like microwave-assisted pretreatment are promising because they attack the root problem—REEs stuck in complex mineral hosts. Still, the transition to industrial-scale operations will require pilot plants, adaptive processing to local geology, and economic models that value co-recovered elements and environmental gains. It’s an exciting avenue, but not a plug-and-play solution."

The path forward will involve technical refinement, pilot demonstrations, and industry interest. If those align, the piles of coal tailings that once posed environmental headaches could instead become strategic repositories of metals we need to build a cleaner future.

Source: sciencealert

Leave a Comment