4 Minutes

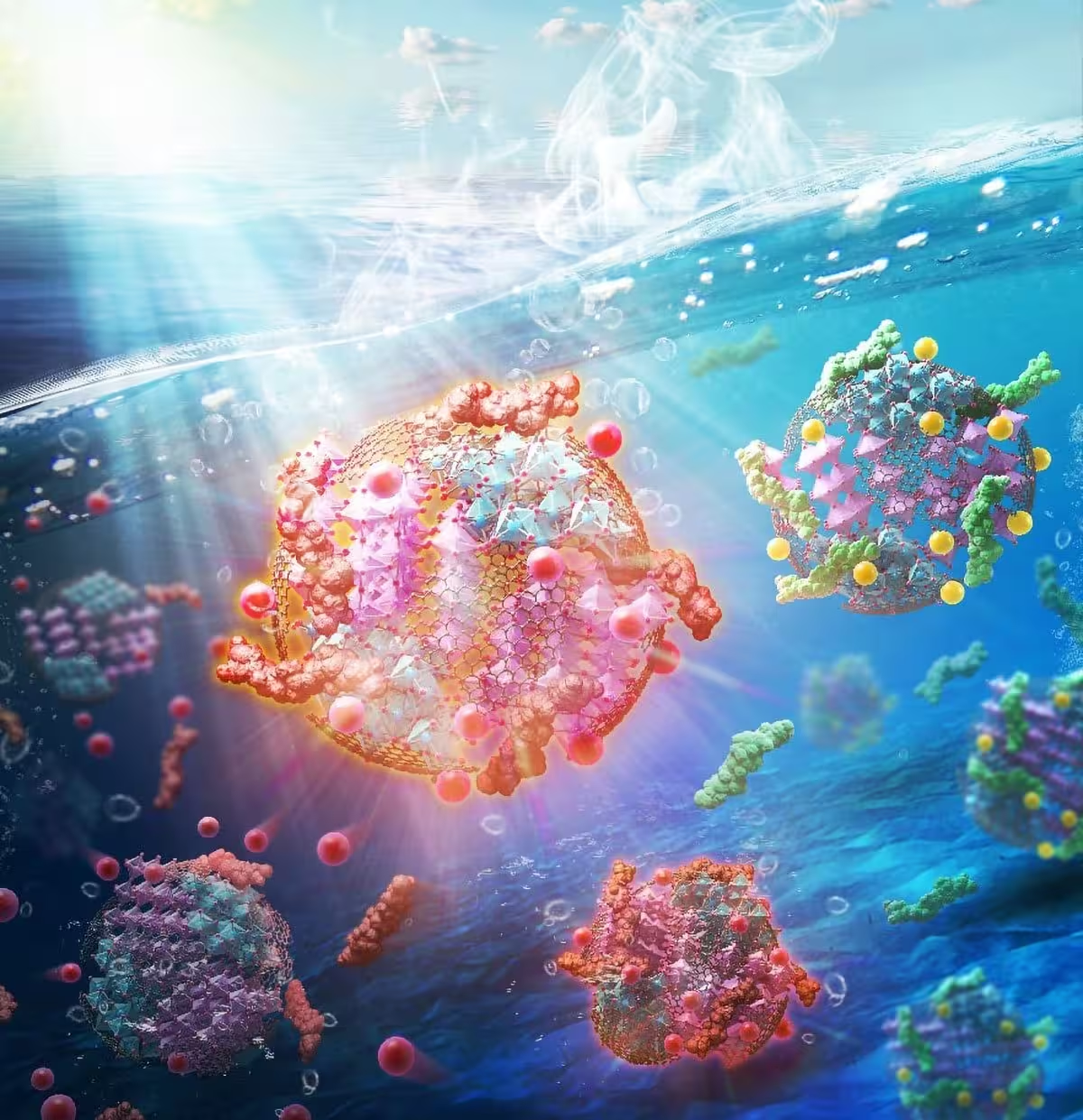

Researchers at the Nagoya Institute of Technology have turned everyday plastic waste into a multifunctional, solar-driven material that can both purify and desalinate water. The new composite—produced by a refined mechanochemical milling method—combines light absorption, heat generation and pollutant adsorption in a single, low-cost particle that could help scale affordable water remediation.

How plastic and a ball mill became a water-cleaning catalyst

The team led by Associate Professor Takashi Shirai used a planetary ball mill to mechanically transform a simple mixture of molybdenum trioxide (MoO3) and polypropylene—the ubiquitous plastic in packaging—into a layered composite. Fine-tuned milling parameters drove chemical and physical changes that produced hydrogen molybdenum bronze (HxMoO3–y), molybdenum dioxide (MoO2), and activated carbon derived from the polypropylene feedstock.

Mechanochemical synthesis—the process of using mechanical force to trigger chemical reactions—offers advantages here: it avoids high-temperature, energy-intensive steps and can repurpose waste plastics as functional carbon components. According to the researchers, the method is energy-efficient and cost-effective compared with many conventional synthesis routes for advanced photocatalysts.

These novel hydrogen molybdenum bronze-molybdenum dioxide/carbon composite particles exhibit exceptional photothermal interface evaporation rate, wide-spectrum photocatalytic activity for the elimination of water pollutants, and sufficient adsorption capacities for heavy metal ions even in darkness. They could form the basis of large-scale, affordable water remediation technologies.

One material, multiple purification modes

What makes the composites notable is their multifunctionality. In laboratory tests the particles showed broad-spectrum light absorption across ultraviolet, visible and near-infrared wavelengths. That allowed two sunlight-driven processes to operate in tandem:

- Photocatalytic degradation: under light, the molybdenum oxide phases act as photocatalysts that break down organic contaminants into less harmful molecules.

- Photothermal evaporation: plasmonic-like behavior and strong light-to-heat conversion rapidly heat water at the particle interface, driving fast evaporation and enabling solar desalination.

Beyond light-driven paths, the retained oxygen-containing activated carbon provides adsorption sites for heavy metal ions, meaning the material can remove contaminants even in darkness. The composites also displayed Brønsted acid catalytic activity, expanding their chemical versatility for degrading certain pollutants.

Why this matters: scalability, cost and circularity

Many promising photocatalysts are expensive or tricky to manufacture at scale. By contrast, the Nagoya team’s approach starts from inexpensive MoO3 and common polypropylene waste, using a scalable milling process. The result is an affordable, multifunctional particle that could be deployed for decentralized water treatment, emergency desalination, or as a component in hybrid solar purification systems.

Imagine a low-cost panel or floatable mat coated with these composites: under sunlight it would evaporate and condense freshwater while simultaneously degrading organics and capturing metal ions. That combination of functions reduces the need for multiple separate treatment steps and could lower infrastructure and maintenance costs.

Next steps and broader applications

The researchers plan to refine milling recipes to apply the mechanochemical strategy to other oxides and plastic types, broadening the library of upcycled, solar-active composites. They expect similar all-in-one catalysts could enhance existing materials, enable new remediation concepts, and contribute to circular-material solutions that lock waste plastics into useful technologies.

Published in ACS Applied Materials & Interfaces, the study demonstrates a tangible route to couple plastic upcycling with solar-driven water treatment—an intersection of environmental remediation and materials innovation that could matter greatly in regions facing water stress and limited resources.

Technology to watch

Key technical terms to follow in related research: mechanochemical synthesis, hydrogen molybdenum bronze, photothermal evaporation, photocatalyst, solar desalination, activated carbon adsorption and circular upcycling of plastics. Together, these advances point toward practical, low-cost designs for water purification that harness sunlight and waste materials, rather than relying solely on rare or expensive components.

Source: scitechdaily

Leave a Comment