10 Minutes

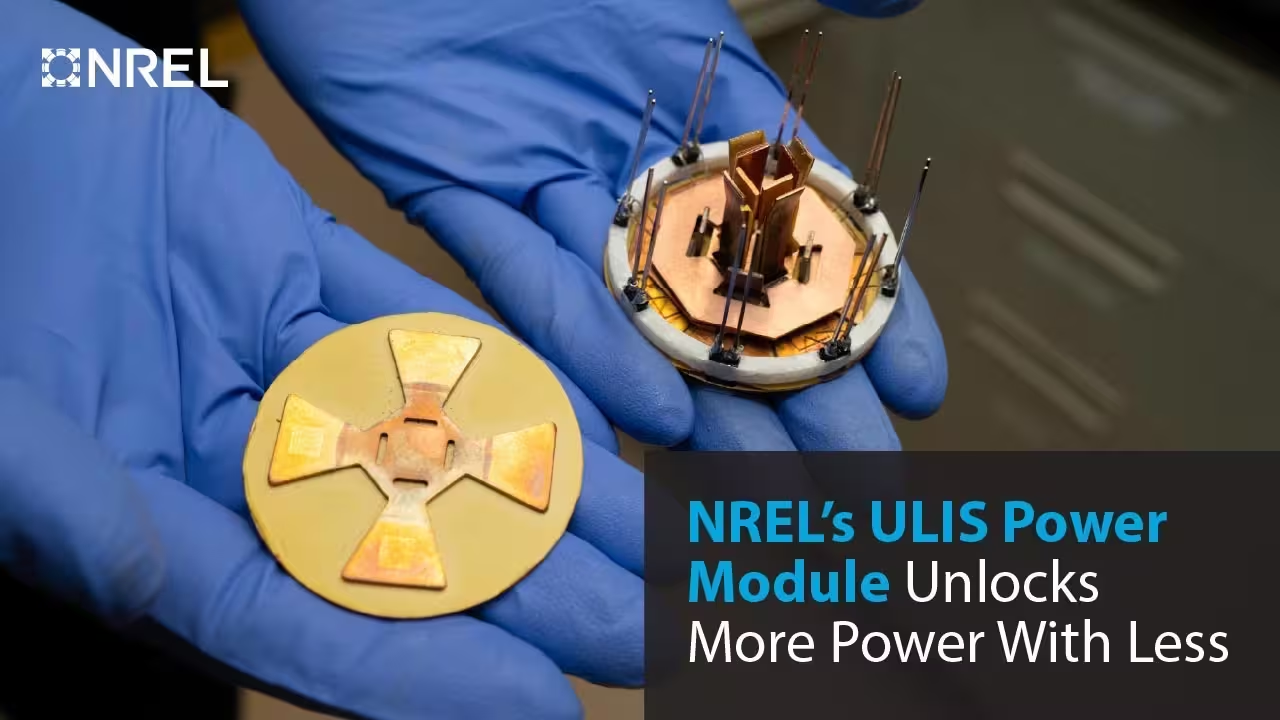

As global electricity demand surges, researchers at the U.S. Department of Energy's National Renewable Energy Laboratory (NREL) have unveiled a compact power module that promises to deliver far more usable energy from existing supplies. Built around silicon carbide semiconductors and an innovative form factor, the Ultra-Low Inductance Smart power module, or ULIS, packs high voltage, high current, and ultrafast switching into a small, manufacturable package.

A smarter way to squeeze more power from what we already have

Demand for electricity is rising fast. Data centers powering artificial intelligence workloads, electric and hybrid vehicles, and advanced manufacturing are among the biggest drivers. Building entirely new generation or transmission infrastructure to match that growth is costly and slow. That is why devices that use electricity more efficiently can have an outsized effect on the energy system.

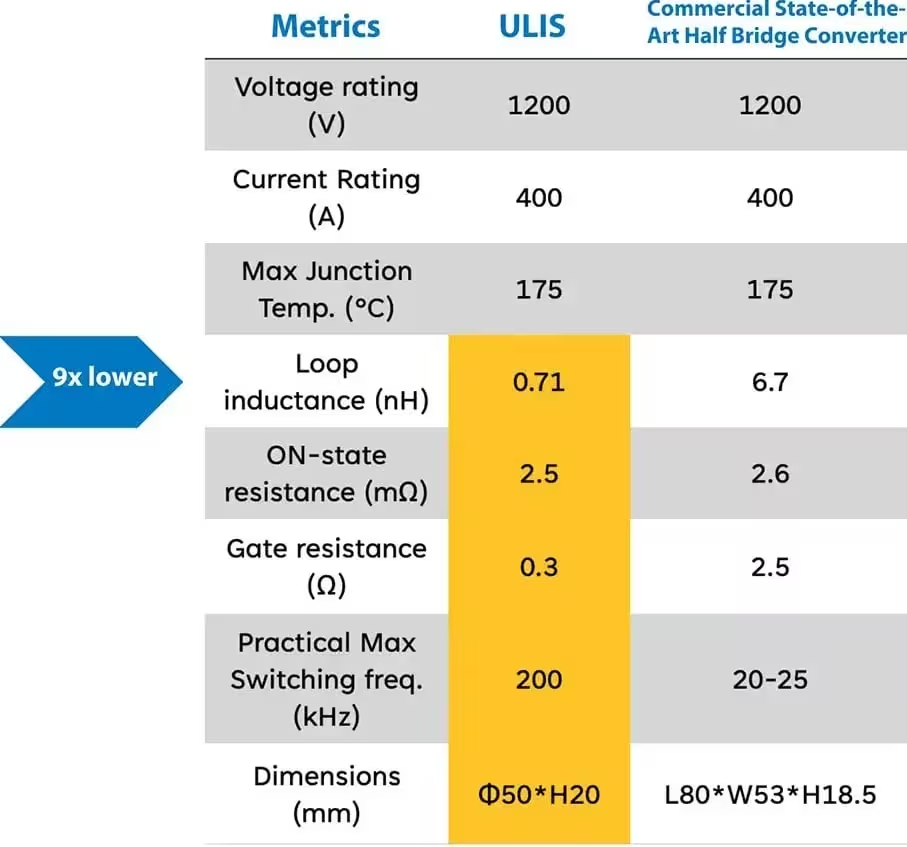

ULIS approaches the problem by rethinking the heart of power conversion: the module that controls how electricity flows between a source and a load. Rated for roughly 1,200 volts and 400 amps, this silicon carbide-based module delivers far higher energy density and switching speed than prior designs. The developers say ULIS can offer about five times the usable energy density of older power modules while occupying less space—traits that make it attractive for data centers, the electrical grid, compact reactors, and heavy-duty platforms such as electric aircraft and military vehicles.

Why low parasitic inductance matters

One of ULIS's technical breakthroughs is its exceptionally low parasitic inductance. Parasitic inductance is an unwanted resistance to rapid changes in current; in power converters it limits switching speed and increases energy loss, heat, and stress on components. By cutting that parasitic inductance by a factor of seven to nine compared with today's leading silicon carbide modules, ULIS can switch currents far more quickly and with much lower loss.

Faster switching and lower losses translate directly into higher efficiency: the same incoming electricity yields more usable output. For high-power applications where milliseconds or microseconds matter, ULIS's ability to control current precisely can make converters smaller, lighter, and cheaper to operate.

As Faisal Khan, NREL's chief power electronics researcher and principal investigator on the project, puts it, ULIS is effectively a future-proofed, ultrafast module designed to make the next generation of converters both affordable and compact. The module also continuously monitors its condition and can predict component failure before it happens, a form of embedded reliability that is especially valuable for aircraft and military deployments.

From 3D ideas to a 2D breakthrough: an engineered face-lift

Much of ULIS's novelty stems from a radical rethink of how the module is arranged. Conventional modules tuck semiconductor devices into a brick-like package. The NREL team abandoned that bulky approach, instead routing circuits around a flattened, octagonal disk. This nearly two-dimensional layout allows many more devices to be placed in a smaller footprint while enabling current paths that cancel magnetic flux—one reason parasitic inductance drops so dramatically.

Design iterations ranged from petal-like configurations to hollow cylinders, but fabrication difficulty and cost repeatedly forced the team to iterate. A near-flat, pancake-style architecture proved to be the sweet spot: easy to make, low-cost to machine on widely available equipment, and high-performing electrically. Team members Shuofeng Zhao and Sarwar Islam led the architecture and layout decisions that balanced circuit complexity with manufacturability.

Materials and manufacturing: lighter, cheaper, and modular

Beyond geometry, ULIS replaces rigid, heavy substrates with a more flexible stack. Where conventional modules bond copper sheets to ceramic bases, ULIS bonds copper to a polymer called Temprion, producing a thinner, lighter core that still conducts well and tolerates heat. The pressure-and-heat bonding approach is compatible with simpler shop tools, reducing build cost from thousands to hundreds of dollars per module.

Manufacturing innovations were critical. NREL engineers devised fabrication steps and tooling that allow intricate architectures to be machined with existing lab equipment, keeping costs down and making the design accessible to more manufacturers. In practical terms, a module that once might have required exotic processes can now be produced with common equipment, enabling faster scaling.

Wireless, modular, and future-ready

ULIS also includes a novel, low-latency wireless control and monitoring capability that lets the module be treated like an isolated, plug-and-play building block. The team has applied for a patent on that communication protocol, which means ULIS could be integrated into systems without bulky control wiring. Imagine stacking modular power bricks in a server rack or swapping out a converter module in an aircraft line-replaceable unit; the wireless layer simplifies such logistics and increases system resilience.

The design is intentionally extensible: while the current iteration uses silicon carbide devices, the module can scale to incorporate newer wide-bandgap semiconductors such as gallium nitride and, eventually, gallium oxide. That adaptability helps future-proof the concept as semiconductor technologies evolve, enabling even higher switching frequencies and efficiencies down the road.

Where ULIS could make the biggest difference

Several real-world applications stand to benefit from ULIS's combination of density, speed, and reliability.

- Modernizing grid conversion: Power entering the grid often requires conversion and conditioning. ULIS's fast, efficient switching can increase the fraction of electricity delivered as usable power, reduce transformer size, and lower long-term maintenance by operating reliably at higher temperatures.

- Compact electric aircraft: Weight and cooling limits are major hurdles for electric vertical takeoff and landing vehicles and other advanced aircraft. A smaller, lighter power converter that wastes less energy can improve range and payload without redesigning entire powertrains.

- High-intensity pulsed power and fusion: Emerging concepts such as compact fusion devices and pulsed-power systems require ultralow inductance components to manage sudden, intense bursts of current. ULIS's low-loss, compact architecture fits that niche well.

- Data center efficiency: Large data centers consume significant power for compute and cooling. More efficient power conversion stages can reduce operating costs and carbon footprints, especially where AI workloads push servers to their limits.

Expert Insight

Dr. Amanda Reyes, a power electronics systems engineer who consults for aerospace integrators, offered a practical perspective: 'What makes a device like ULIS interesting is not a single metric, but the combination: high voltage and current handling, ultrafast switching, low inductance, and manufacturability. You can have a great lab demo, or you can have something that industry can build at scale. ULIS is aiming for both. For aircraft and military systems, the built-in diagnostics and the module's lightweight construction are game changers.'

She added a caution: 'Integration into a real product will require further testing under vibration, altitude, and thermal cycling. But the initial architecture looks promising for rapid adoption in systems where size, weight, and reliability are critical.'

Scientific and technical context for non-specialists

To understand why ULIS matters, it helps to know a few basics. Power converters transform electricity from one form to another—changing voltage, frequency, or converting between AC and DC. The speed at which switches inside converters change state controls efficiency and size. Faster switching typically allows smaller magnetic components and capacitors, but also raises technical challenges such as voltage overshoot and electromagnetic interference. Parasitic inductance makes these issues worse.

Wide-bandgap semiconductors like silicon carbide and gallium nitride tolerate higher voltages, higher temperatures, and switch faster than conventional silicon. Pairing these devices with an ultra-low-inductance layout and an architecture optimized for fabrication unlocks performance levels previously limited to expensive, bespoke systems.

In short: the materials let you push performance, the layout prevents those gains from being eaten by parasitic effects, and the manufacturing choices determine whether industry can actually build the modules at scale and cost.

Next steps and future prospects

NREL has built and tested ULIS prototypes in its labs and is moving toward demonstration in representative environments. The roadmap includes broader reliability testing, integration with power converters in partner systems, and scaling manufacturing approaches for commercial supply chains. If those steps proceed smoothly, ULIS or ULIS-inspired designs may appear inside next-generation servers, electric aircraft prototypes, and grid converters within a few years.

More broadly, the ULIS effort highlights a practical path to closing the gap between rising electricity demand and available delivery infrastructure: improve conversion efficiency, shrink power electronics, and make those improvements affordable and manufacturable. That combination may not be as flashy as building a new power plant, but it can yield immediate gains across many sectors that collectively consume large shares of the world’s electricity.

Where will ULIS show up first? Expect trials in high-value, high-stress applications such as aerospace and defense, followed by pilot deployments in data centers and grid-edge systems. From there, cost reductions and manufacturing scale could lead to wider adoption across transportation and industrial motors—sectors where even a few percentage points of efficiency translate into large economic and emissions benefits.

Source: scitechdaily

Comments

skyspin

Feels overhyped tbh, cool tech though. Scaling manuf + supply chain headaches will decide winners, not a clever PCB layout alone.

labcore

Sounds promising but is this validated for vibration, altitude, and thermal cycling? Lab demos are nice but real-world stress? skeptical.

mechbyte

wow didnt expect the pancake layout to matter so much... SiC + low inductance = real gains, if they can scale it this could reduce datacenter power waste big time

Leave a Comment